Are you frustrated by a leaking shut-off valve? This is one of the most common plumbing problems homeowners encounter.

Repairing a toilet shut-off valve can seem daunting, but with the right knowledge and tools, it’s a straightforward process that can save you both time and money. The shut-off valve is an essential component of your plumbing system, allowing you to control the water flow to your toilet. Over time, these valves can wear out, leak, or stop functioning properly, potentially leading to water wastage or damage.

This guide on how to repair toilet shut off valve will walk you through the steps to troubleshoot and repair a faulty toilet shut off valve, ensuring your plumbing system functions efficiently and reliably.

What Are the Causes of a Faulty Toilet Shut-Off Valve?

There are several reasons why your toilet shut-off valve may be malfunctioning. Some common causes include:

- Age and Wear: Like any plumbing component, the shut-off valve can deteriorate over time due to regular use and exposure to water.

- Mineral Buildup: Hard water can leave mineral deposits inside the valve, causing it to clog or become stiff.

- Corrosion: Constant contact with water can cause rust and corrosion on metal valves, leading to leaks or difficulty turning the valve handle.

- Faulty Installation: If the shutoff valve was not installed properly, it may not function correctly.

- Physical Damage: External factors such as accidental hits, extreme temperatures, or natural wear and tear can damage the shut-off valve.

- Improper Use: Excessive force when turning the valve handle or repeatedly opening and closing it can damage it over time.

It is important to regularly inspect and maintain your shut-off valves to ensure they function properly in an emergency.

What Will You Need?

To inspect, maintain, or replace a shut-off valve, you will need the following tools and materials:

- Adjustable Wrench: For loosening or tightening the valve connections.

- Pipe Cutter or Hacksaw: If the valve or pipe needs to be removed or replaced.

- Teflon Tape: Ensure a secure and leak-proof connection when reinstalling the valve.

- Bucket or Towels: To catch any water that may spill.

- Replacement Valve: If the existing shut-off valve is damaged or non-functional.

- Gloves and Safety Glasses: These are for personal protection while handling tools or old components.

- Flashlight: To improve visibility in tight or poorly lit spaces.

- Plumber’s Tape Measure: To ensure that the replacement valve is the proper size for the pipe.

Having these tools and materials ready will make the process more efficient and help ensure a successful outcome.

10 Easy Steps on How to Repair Toilet Shut Off Valve

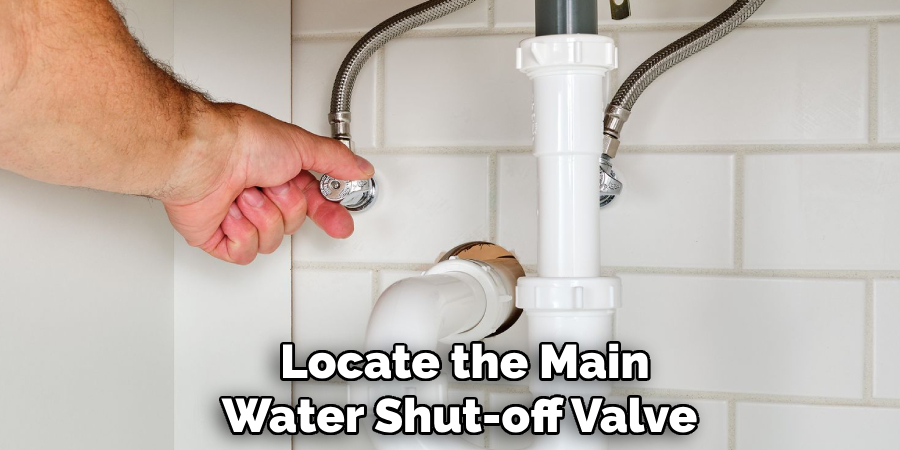

Step 1. Turn Off the Main Water Supply:

Locate the main water shut-off valve in your home, typically near the water meter or where the main water line enters the house. Turn the valve clockwise to stop the water flow completely. Open a faucet nearby to release any remaining water pressure in the pipes. This step ensures no water will flow while working on the toilet shut-off valve, preventing leaks or water damage.

Step 2. Drain the Water from the Toilet Tank:

Flush the toilet to empty as much water as possible from the tank. Once flushed, use a sponge, towel, or small cup to remove any remaining water from the bottom of the tank. Ensure the tank is completely dry to avoid spilling water during the repair process. This step is crucial for keeping the workspace clean and preventing unnecessary mess.

Step 3. Place a Bucket or Towel Beneath the Valve:

Position a small bucket or a thick towel directly beneath the toilet tank where the valve is located. This is essential to catch any remaining water or debris that may spill out while working on the valve. Using a bucket ensures no water reaches the floor, while a towel can help absorb any unexpected drips effectively.

Double-check that the area is securely covered to protect the surrounding floor from potential damage and make cleaning up easier after the repair. This precaution minimizes the risk of creating secondary messes during the process.

Step 4. Remove the Old Shut-Off Valve:

To remove the old shut-off valve, ensure the water supply is completely turned off to avoid accidental leaks. Next, a wrench or adjustable pliers are used to loosen the nuts and secure the valve to the pipe. Carefully unscrew the valve, keeping a firm grip to prevent damaging the surrounding plumbing or shifting the pipe. If the valve is corroded or stuck, apply a penetrating lubricant and allow it to sit for a few minutes before loosening it again.

For soldered valves, you may need a propane torch to heat the joint and melt the solder for removal, but exercise extreme caution when using such tools. Ensure all flammable materials are cleared from the area, and consider using a flame-protective barrier to shield nearby surfaces.

Step 5. Inspect the Pipe Threads:

Scrutinize the pipe threads for any signs of damage, such as cracks, excessive wear, or corrosion. Damaged threads can lead to improper sealing, causing leaks once the system is reassembled. Use a wire brush to clean the threads, removing any debris, old sealant, or rust that might hinder a secure fit. If the threads are severely worn or damaged beyond repair, replacing the pipe or fitting may be necessary to ensure a proper connection.

Apply thread sealant or plumber’s tape generously but evenly to the threads before reattaching the valve or coupling, which will help create a watertight seal and prevent leaks. Always double-check the alignment of the threads during reassembly to avoid cross-threading, which can further damage the pipe or fittings. Inspecting and preparing the pipe threads properly can save you significant effort and avoid potential complications later.

Step 6. Apply Plumber’s Tape to the Threads:

Clean the threads thoroughly to remove dirt, old sealant, or debris. Once the threads are clean, take a roll of plumber’s tape and wrap it tightly around the threaded end of the pipe. Begin at the base of the threads and work your way upwards, overlapping slightly with each turn to ensure complete coverage. Wrap the tape in the direction of the threads to prevent it from unraveling when you screw on the fitting.

Typically, two to three layers of tape are sufficient for a secure seal. When finished, press the tape firmly into the threads to ensure it adheres properly and provides maximum effectiveness.

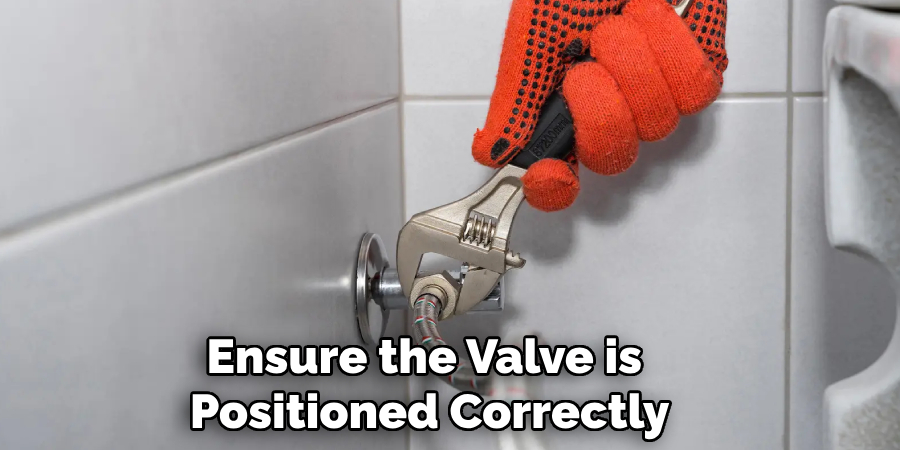

Step 7. Attach the New Shut-Off Valve:

Carefully align the new shut-off valve with the prepared pipe threads. Begin threading the valve onto the pipe by hand, turning it clockwise to ensure it tightens properly. Once the valve is hand-tight, use an adjustable wrench to secure it further, taking care not to overtighten, as this could damage the threads or the valve.

Ensure the valve is positioned correctly, with the handle accessible and able to move freely for easy future use. Double-check for any gaps or misalignments before proceeding to the next step.

Step 8. Reconnect the Supply Line:

Carefully align the supply line with the valve’s threaded outlet. Begin threading it by hand, turning it clockwise to ensure proper alignment and prevent cross-threading. Once the connection is hand-tight, use a wrench to gently tighten it, but avoid overtightening to prevent damage to the fittings. After securing the supply line, ensure the connection is firm and properly seated. This step is crucial to prevent leaks when the water supply is turned back on.

Step 9. Turn On the Main Water Supply:

Slowly turn on the main water supply by opening the shut-off valve. Monitor the newly installed connections for any signs of leakage. If you notice any drips or water escaping, immediately turn off the water supply and carefully tighten the fittings as needed. Once you’ve confirmed there are no leaks, allow the water to flow through the system for a few minutes to flush out any debris that may have entered during installation. This ensures clean and unobstructed water flow.

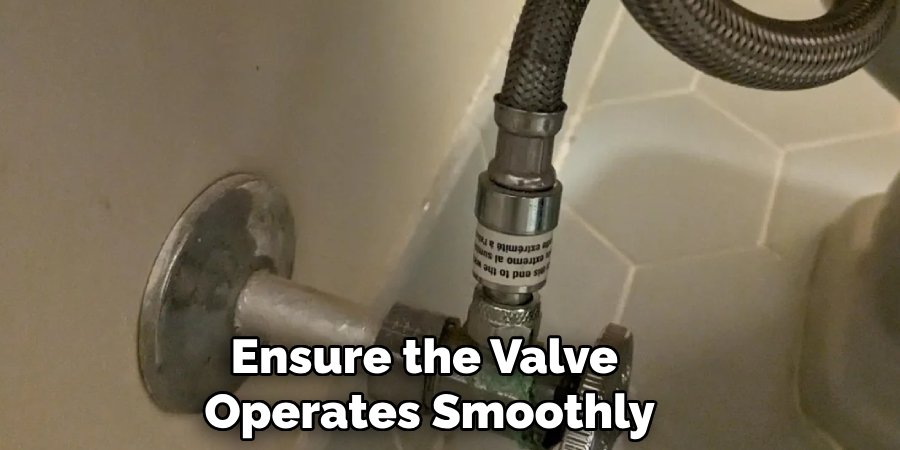

Step 10. Test the New Shut-Off Valve:

To test the new shut-off valve, turn it to the “off” position and ensure no water flows from the connected fixtures. This confirms that the valve effectively stops the water supply. Next, turn the shut-off valve to the “on” position and observe the water flow. Check for any irregularities, such as low pressure, which could indicate an issue with the valve or the installation process. Additionally, carefully inspect the valve and surrounding connections for any signs of leaks or drips.

It’s essential to address any problems immediately to prevent potential water damage. Repeat this process a few times to ensure the valve operates smoothly and consistently without any resistance or unusual sounds.

By following these steps, you can successfully replace or repair your toilet shut-off valve and ensure it functions properly.

Conclusion

How to repair toilet shut off valve may seem intimidating at first, but with the right tools and a methodical approach, it can be a straightforward task.

Always prioritize safety by turning off the water supply and thoroughly checking for leaks after completing the repair. Proper maintenance of the shut-off valve will help prevent future issues and ensure the smooth operation of your plumbing system.

You can effectively handle this repair and avoid unnecessary expenses with patience and attention to detail.