Attaching a brass pipe is a straightforward process that requires the right tools and techniques to ensure a secure and leak-free connection.

Brass pipes are commonly used in plumbing systems due to their durability, corrosion resistance, and ability to handle high temperatures. Whether you are working on a new plumbing project or repairing an existing system, understanding the proper steps for attaching brass pipes is critical for achieving a reliable result.

This guide on how to attach brass pipe will walk you through the basics of preparing, connecting, and sealing brass pipes effectively.

Why Choose Brass Pipes?

Brass pipes are widely used in plumbing systems for a variety of reasons. Here are some of the key benefits of using brass pipes:

Durability

Brass is a strong and long-lasting material, making it ideal for use in plumbing applications where pipes may be exposed to high levels of pressure and stress. It is also resistant to corrosion, ensuring that your plumbing system remains in good condition for longer periods of time.

Versatility

Brass pipes come in a variety of sizes and shapes, making them suitable for various plumbing projects. Whether you are working on a small home repair or a large commercial installation, brass pipes can be easily adapted to fit your specific needs.

Aesthetic appeal

Aside from their functional benefits, brass pipes also add an element of style and sophistication to any plumbing system. Their golden hue adds a touch of elegance, making them a popular choice for both traditional and modern designs. Additionally, brass pipes are highly versatile and can be polished or brushed to achieve a desired finish, making them suitable for a wide range of interior design styles.

Durability

Brass is known for its durability and resistance to corrosion, which makes it an ideal material for plumbing pipes. Unlike other materials like plastic or copper, brass pipes can withstand high pressure and temperature without cracking or deteriorating over time. This makes them a long-lasting option for your plumbing needs and can save you money in the long run by avoiding frequent replacements.

Low Maintenance

One of the greatest advantages of using brass pipes is their low maintenance requirements. Unlike other materials that may require regular cleaning or treatment to prevent rusting, brass pipes are naturally resistant to corrosion. This means that you can install them and forget about them, without having to worry about constant upkeep. Additionally, brass is also resistant to bacterial growth, making it a hygienic choice for plumbing systems.

Needed Materials

When installing brass pipes, you will need to have a few materials on hand. These include:

Brass Pipes

As previously mentioned, brass pipes come in different sizes and can be found at most hardware stores. Make sure to measure the length and diameter of the pipes needed for your specific project before purchasing.

Pipe Wrench

A pipe wrench is a tool used for tightening or loosening pipes. It has sharp teeth which grip onto the smooth surface of brass pipes, allowing you to easily adjust and secure them in place.

Teflon Tape

Teflon tape, also known as plumber’s tape, is a thin white tape that is wrapped around threaded connections to create a tight seal. This is especially important when working with brass pipes because they can be prone to leaks if not properly sealed.

Pipe Cutter

If you need to cut your brass pipes to specific lengths, a pipe cutter is essential. This tool allows you to make clean, straight cuts without damaging the pipe. It works by rotating a blade around the pipe, gradually tightening until it cuts through.

Pipe Reamer

After cutting your brass pipes, you may notice rough edges or burrs on the inside of the pipe. These can hinder water flow and cause leaks. A pipe reamer is a handy tool that smooths out these rough edges and ensures a proper fit for connections.

10 Step-by-Step Guidelines on How to Attach Brass Pipe

Step 1: Measure and Cut the Pipe

Start by measuring the length of the brass pipe you need using a measuring tape. Mark the desired length clearly with a marker or pencil to ensure accuracy. Once marked, use a pipe cutter to make a clean and straight cut. Rotate the cutter around the pipe, tightening it slightly with each turn until the pipe is fully cut.

This ensures precise dimensions and smooth edges, which are essential for proper fitting and sealing. After cutting, use a pipe reamer to remove any burrs or rough edges from the inside of the pipe.

Step 2: Remove Any Burrs or Rough Edges

After making the cut, it is important to ensure the brass pipe’s interior and edges are smooth for optimal performance and a secure connection. Use a pipe reamer or a round file to carefully remove any burrs or rough edges.

Insert the tool into the cut end of the pipe and twist it gently until the edges are smooth. Be sure to check both the inside and outside of the pipe for any imperfections. Properly deburred edges help prevent leaks, enhance safety, and ensure a professional-quality finish.

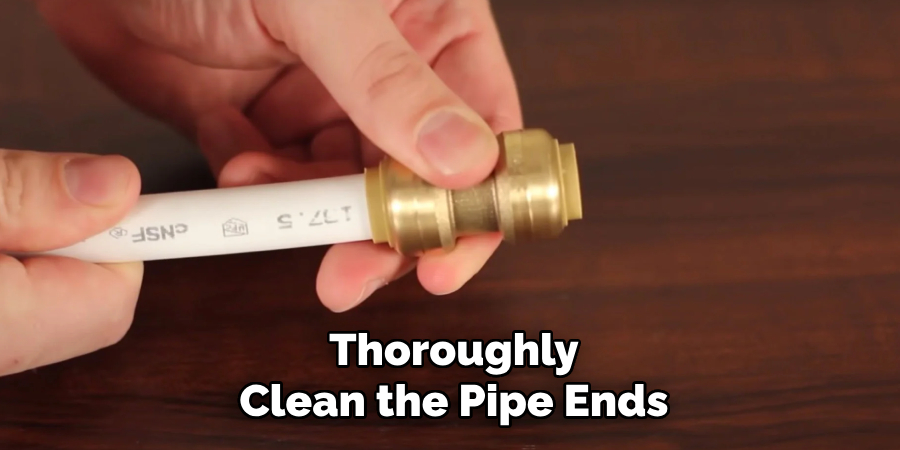

Step 3: Clean the Pipe Ends

After deburring, it is essential to thoroughly clean the pipe ends to remove any remaining debris, oil, or dirt that could impact the connection. Use a clean, dry cloth or a dedicated pipe cleaning pad to wipe the interior and exterior surfaces of the cut ends. For stubborn residues, consider using a mild solvent or cleaning solution suitable for brass.

Ensure the pipe ends are completely dry before proceeding to the next step, as moisture can interfere with the fitting process. Proper cleaning ensures a strong bond and contributes to the durability of the connection.

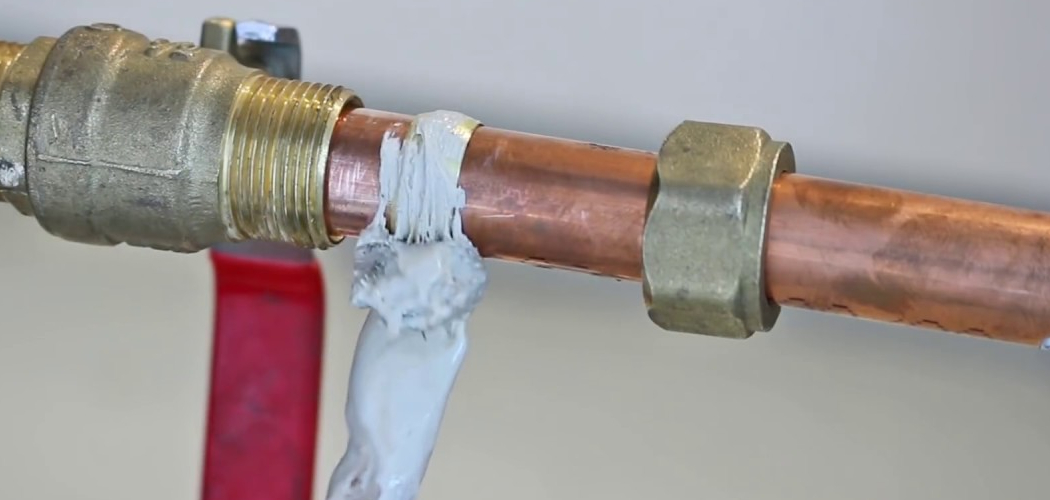

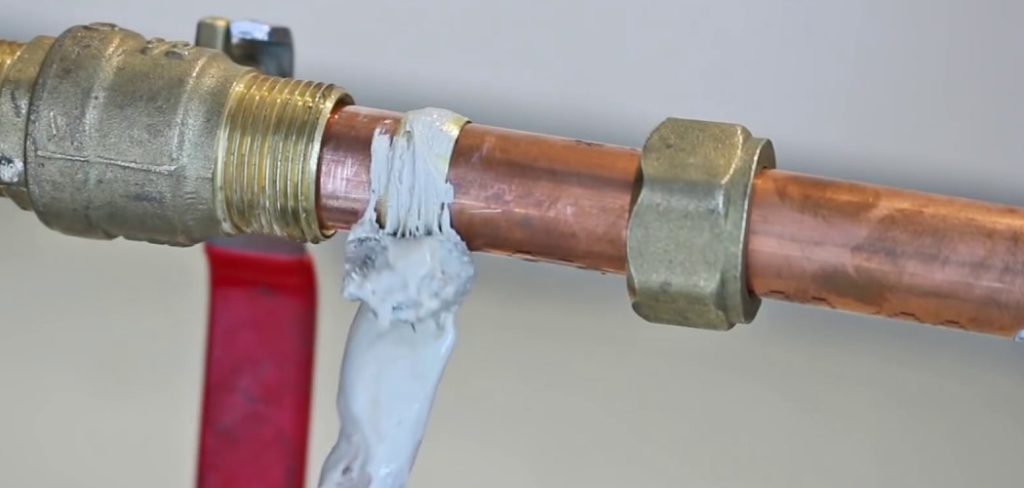

Step 4: Apply Flux to Both Ends

Using a brush or applicator, evenly apply a thin layer of flux to the outside of the pipe ends and the inside of the fittings. Flux not only helps to clean the surfaces further but also facilitates the soldering process by preventing oxidation and ensuring the solder flows smoothly into the joint.

Be sure to cover all areas that will come into contact during the fitting to create a solid and leak-free connection. Avoid applying excess flux, as this could lead to residue buildup or affect the integrity of the joint.

Step 5: Insert Pipe into Fitting

Carefully insert the pipe into the fitting, ensuring it is fully seated. Rotate the pipe slightly while inserting to evenly distribute the flux and help create a secure connection. Make sure the pipe fits snugly within the fitting without any gaps.

Double-check the alignment to confirm that the components are straight and properly positioned, as this will play a crucial role in maintaining a strong, leak-free joint during and after the soldering process.

Step 6: Heat the Joint with a Torch

Using a propane or acetylene torch, apply heat evenly around the joint where the pipe and fitting connect. Begin by warming the fitting first, as it typically requires more heat due to its thicker material. Move the flame back and forth continuously to avoid overheating a single spot, which could damage the pipe or fitting.

Continue heating until the flux begins to bubble and take on a slightly clear, glossy appearance—this indicates that the joint has reached the optimal temperature for soldering. Always exercise caution while handling the torch and wear proper safety gear to prevent accidents.

Step 7: Apply Solder

Once the joint has reached the optimal temperature, carefully touch the tip of the solder to the joint at the edge where the pipe meets the fitting. The heat from the joint should melt the solder instantly—there’s no need to apply the solder directly to the flame. Allow the molten solder to flow naturally around the joint, following the heat, to create a uniform seal.

If done correctly, capillary action will pull the solder into the gap between the pipe and fitting, ensuring a strong, watertight bond. Avoid overloading the joint with excess solder, as this can weaken the connection or lead to drips. After applying the solder, remove the flame and allow the joint to cool naturally before handling.

Step 8: Remove Torch and Wipe Excess Solder

Once the solder has flowed evenly around the joint, carefully remove the torch. Be cautious not to disturb the joint while it is still hot. Immediately after removing the torch, use a clean, dry rag to wipe away any excess solder from the surface of the joint.

This ensures a neat finish and prevents any unwanted solder buildup that could interfere with the system’s functionality. Allow the joint to cool completely before proceeding to the next step or pressure testing the connection.

Step 9: Let the Joint Cool

After wiping away any excess solder, allow the joint to cool naturally to room temperature. Avoid touching or applying pressure to the joint during this cooling period, as this could weaken the connection or cause deformation.

Proper cooling ensures the joint solidifies fully and maintains its integrity. Once the joint is completely cool, you can inspect it for any imperfections before moving on to the next stage of the process.

Step 10: Repeat Steps for Other Joints

With the first joint completed and inspected, proceed to repeat the process for any additional joints. Ensure that you follow each step carefully, from cleaning the surfaces to allowing the joint to cool naturally. Consistency is critical to achieving reliable and durable connections across all joints. Take your time to maintain precision and inspect each joint thoroughly before moving forward. Proper repetition ensures the overall quality and functionality of the final assembly.

Following these steps on how to attach brass pipe fittings can also help in preventing any potential leakage or damage to the pipes. It is essential to maintain the integrity of the connections, especially if they will be used for transporting fluids or gases.

Once all joints have been properly attached and inspected, it is important to test the system before use. This can be done by running water through the pipes or pressurizing them with air. Any signs of leakage or weak connections should be addressed immediately.

Conclusion

In conclusion, properly attaching and inspecting brass pipe fittings is crucial for ensuring a safe and durable piping system. By carefully following the correct procedures and thoroughly testing the connections, potential issues such as leaks or weak fittings can be identified and resolved early.

Taking the time to secure these components not only extends the lifespan of the system but also provides peace of mind when it comes to transporting fluids or gases safely.