Connecting a tub drain is an essential step in ensuring your bathtub functions properly and drains water efficiently. Whether you’re installing a new bathtub or replacing an old drain, the process requires attention to detail and the right tools. This guide will provide you with clear and straightforward instructions for how to connect tub drain successfully, even if you’re new to plumbing.

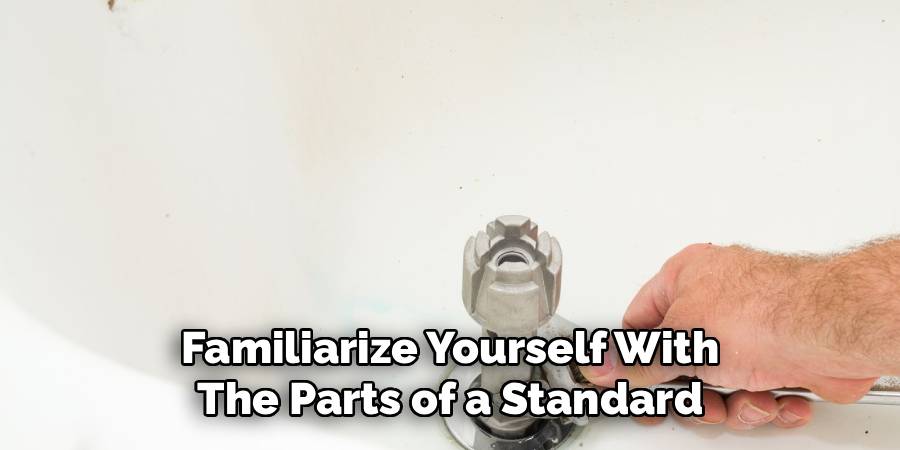

Understand the Tub Drain Components

Before you begin the installation process, it’s important to familiarize yourself with the key components of a tub drain system. A typical tub drain consists of the following parts:

- Drain Flange: This is the visible part of the drain inside the bathtub, where water flows out. It is usually secured with screws and sealed with plumber’s putty.

- Rubber Gasket: Located beneath the drain flange, this gasket creates a watertight seal between the tub and the drain to prevent leaks.

- Overflow Plate: Positioned on the side of the tub, this component prevents the tub from overfilling by channeling excess water to the drain pipe.

- Drain Elbow: A curved pipe that connects the tub’s drain to the main waste pipe. It allows water to flow smoothly out of the bathtub.

- Tailpiece: A straight pipe that extends downward from the drain elbow or overflow assembly to connect with the P-trap.

- P-Trap: This curved pipe holds a small amount of water to block sewer gases from entering your bathroom through the drain.

Understanding these components and how they work together will make the installation process much easier and ensure a functional and leak-free tub drain system.

Tools and Materials You’ll Need

Before starting the installation or replacement of a bathtub drain, it’s essential to have the right tools and materials ready. Here’s a list of what you’ll need:

Tools:

- A pipe wrench or an adjustable wrench is used for tightening and loosening connections.

- Screwdrivers (flathead and Phillips) to remove or secure screws.

- Drain wrench or smart dumbbell wrench for removing and installing the drain flange.

- A plumber’s putty knife for applying or scraping off plumber’s putty.

- A utility knife to cut through caulk or excess putty.

- Channel-lock pliers for gripping and turning nuts or fittings.

- A bucket and rags to catch water and clean up spills.

- A measuring tape to ensure the correct lengths and spacing of pipes.

Materials:

- Plumber’s putty to seal the drain flange.

- Teflon tape for sealing threaded connections.

- Replacement drain kit or parts, such as the flange, tailpiece, and stopper, as needed.

- ABS, PVC, or metal pipes (if additional piping is required).

- Silicone caulk for sealing joints if necessary.

Having these tools and materials on hand will make the process more efficient and help ensure a successful outcome.

10 Methods How to Connect Tub Drain

1. Understand the Components of a Tub Drain Assembly

Before beginning any installation, familiarize yourself with the parts of a standard tub drain. These include the drain flange (the visible part in the bottom of the tub), the drain body (or shoe), the overflow pipe and cover, the linkage or stopper, and the P-trap that connects to your main plumbing line. Knowing how these parts interact will guide you through each step of the connection process. Most tub drains come in a kit and include all necessary parts, so organizing them beforehand helps prevent confusion during installation.

2. Apply Plumber’s Putty to Seal the Drain Flange

To create a watertight seal between the bathtub and the drain flange, roll a generous amount of plumber’s putty into a snake-like rope and press it around the underside of the flange. Place the flange into the tub’s drain hole and press it down firmly. The putty will ooze out slightly—this is normal and indicates a good seal. Wipe away the excess after tightening the flange. Avoid using silicone in place of putty unless the manufacturer specifies it, as putty remains flexible and easier to remove if needed.

3. Secure the Drain Flange from Beneath Using the Drain Shoe

From beneath the tub, align the drain shoe (or waste shoe) with the threads of the drain flange. Use a drain wrench or a tub drain tool to tighten the flange into the shoe from above while holding the shoe steady below. Ensure it’s tightened firmly but avoid overtightening, which could crack the tub or deform the gasket. This connection is crucial as it forms the main pathway for water to exit the tub. If access is difficult, you may need an assistant to hold the components in place while you tighten.

4. Install the Overflow Assembly with Gasket

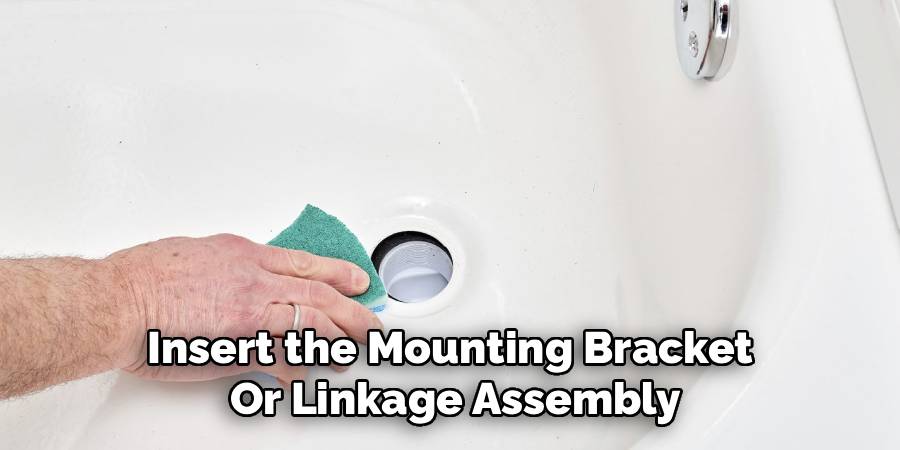

Next, position the rubber overflow gasket between the tub and the overflow pipe to prevent leaks behind the tub wall. Slide the gasket onto the overflow pipe, line it up with the tub’s overflow opening, and insert the mounting bracket or linkage assembly. Secure the overflow cover with screws from the inside of the tub. The gasket creates a tight seal that prevents water from escaping into the wall if the tub is overfilled or splashed. Always ensure the gasket is not twisted or pinched during installation.

5. Connect the Waste Tee and Test Fit the Drain Pipes

With both the drain shoe and overflow in place, connect the two using the waste tee—a T-shaped fitting that joins the horizontal and vertical pipes. Dry-fit all drain components (without glue or tightening) to ensure proper alignment. This step is vital to confirm that all pipes and fittings will sit flush and not require excessive force, which could lead to misalignment or leaks. Most tub drains use slip joints or compression fittings, which allow for some flexibility during adjustment.

6. Tighten Slip Nuts and Compression Fittings Securely

Once everything is test-fitted properly, tighten all slip nuts and compression fittings using a pair of adjustable pliers or a pipe wrench. Hand-tighten first, then use tools to snug them another quarter-turn. Be cautious not to overtighten, as this can damage washers or deform fittings. Each connection should be watertight but not strained. This includes connections between the waste shoe, overflow pipe, waste tee, and down to the P-trap. A properly tightened system reduces the risk of water leakage under the tub.

7. Connect the Drain Assembly to the P-Trap and Main Drain Line

The final connection involves linking the tub’s drain system to the P-trap, which in turn connects to the main house drain line. The P-trap retains a small amount of water to block sewer gases from entering your bathroom. Ensure the vertical tailpiece from the drain connects snugly into the trap inlet. Use PVC primer and cement for solvent-welded fittings or tighten slip joints for mechanical fittings. A level should be used to verify that the drain line slopes slightly downward to allow for proper drainage.

8. Check for Proper Alignment and Slope

Improper slope or misaligned pipes can cause slow draining or stagnant water. Before sealing everything, check the alignment of your drain pipes. The horizontal runs should slope downward about 1/4 inch per foot toward the P-trap. Use a level to confirm this angle. Also, verify that the overflow and drain holes line up correctly with their respective pipe inlets. Adjust as needed before final tightening. Ensuring proper slope and alignment helps prevent clogs and standing water in the tub.

9. Test the Drain System for Leaks

Once fully connected, it’s essential to test the entire assembly before enclosing or sealing any walls or floors. Plug the tub drain with a stopper and fill the tub with a few inches of water. Observe the drain and overflow for any signs of dripping or seepage. Remove the stopper to watch for leaks during draining. Also, inspect the joints under the tub, including the P-trap. If leaks are found, gently tighten the affected connections or reapply plumber’s putty or gaskets as needed.

10. Finish with Silicone Caulk Around the Drain Flange (Optional)

For extra protection against water intrusion, especially with certain tub materials like fiberglass, you can apply a thin bead of waterproof silicone caulk around the edge of the drain flange where it meets the tub surface. Smooth the caulk with a damp finger or caulk tool and allow it to cure per the manufacturer’s instructions. This step is optional, but it can help prevent water from seeping under the flange, especially if the tub flexes slightly under weight.

Conclusion

Connecting a tub drain may seem like a technical plumbing job, but with the right steps and attention to detail, it can be completed successfully by most DIYers. From applying plumber’s putty to aligning and tightening the waste tee and overflow assembly, each step contributes to a watertight and functional drainage system. These ten elaborated methods offer a thorough roadmap for ensuring your bathtub not only drains efficiently but also stays leak-free for years. Take your time, double-check your fittings, and your project will be a success from the ground up. Thanks for reading our blog post on how to connect tub drain! We hope you found it helpful and informative.