Cutting toilet bolts is a necessary task when installing or replacing a toilet. Over time, bolts may become too long, corroded, or difficult to handle, requiring careful trimming to ensure a perfect fit and a neat appearance. With the right tools and techniques, this process can be simple and safe. This guide on how to cut toilet bolts will walk you through the steps to efficiently and effectively cut toilet bolts, ensuring a secure installation without damaging your toilet or flooring.

Why Cut Toilet Bolts?

Toilet bolts are essential for securing the toilet to the floor and creating a seal between the toilet and the plumbing system. If the bolts are too long, they can cause stability issues and interfere with proper flushing. On the other hand, if they are too short, they may not provide enough support, which can result in leaks or even damage to your flooring. Therefore, it is crucial to cut toilet bolts to the correct size for a successful installation.

It is also common for bolts to become corroded or rusted over time, making them difficult to remove during a toilet replacement. In such cases, cutting the bolts may be necessary to avoid damaging the toilet or plumbing system.

Tools You Will Need

Before starting, make sure you have all the necessary tools on hand:

Adjustable Wrench:

An adjustable wrench is a versatile tool that can be used to tighten or loosen various sizes of nuts and bolts, including toilet bolts. Make sure the jaw size of your wrench fits the bolt properly for better grip and control.

Hacksaw:

A hacksaw with a fine-tooth blade is best suited for cutting metal toilet bolts. It allows for more precise cuts and reduces the risk of damaging other parts of the toilet.

File:

A file is useful for smoothing out any rough edges left after cutting the bolt. This will prevent any snags or scratches when installing the new toilet.

Protective Gear:

It is important to protect yourself while working with tools. Wear safety glasses to protect your eyes from any flying debris and gloves to prevent cuts or scrapes.

8 Step-by-step Instructions on How to Cut Toilet Bolts

Step 1: Prepare the Toilet for Installation

Before cutting the toilet bolts, ensure the toilet is properly positioned and ready for installation. Start by placing the toilet on the flange to check the alignment and ensure the bolts are visible through the mounting holes in the toilet base. Adjust the positioning as needed to ensure a proper fit.

Once aligned, mark the desired length of the bolts with a pencil or marker, leaving just enough length above the nuts to secure the toilet firmly. This preparation ensures that the bolts are trimmed to the correct size, preventing unnecessary adjustments later in the process.

Step 2: Remove the Nuts and Washers

Before cutting the toilet bolts, you will need to remove the nuts and washers that secure the bolts in place. Using the adjustable wrench, carefully loosen the nuts by turning them counterclockwise. Once loose, remove both the nuts and washers and set them aside in a safe location to prevent losing any pieces.

This step ensures that the area around the bolts is clear and reduces the risk of damaging the hardware or threads while cutting. With the nuts and washers removed, you can proceed to cut the bolts cleanly and without obstruction.

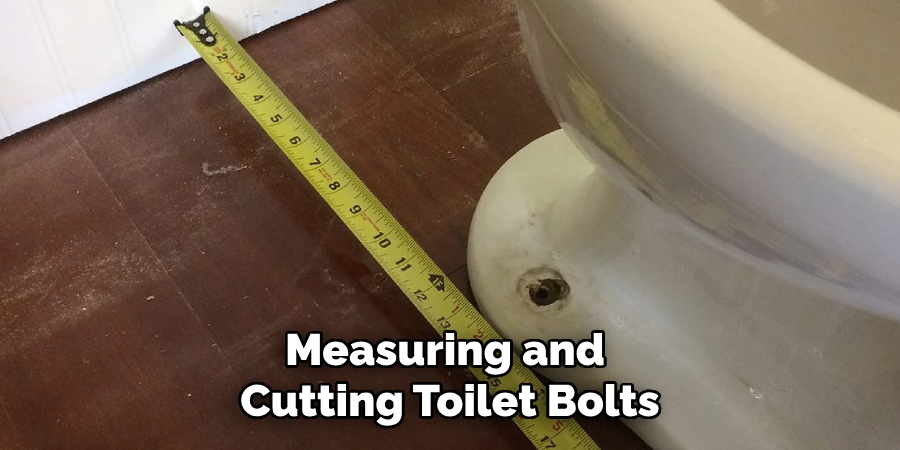

Step 3: Measure the Desired Length

With the nuts and washers removed, carefully measure the desired length of the toilet bolts. Use a ruler or measuring tape to ensure accuracy, and leave enough bolt length to allow the nuts to be securely tightened after reinstallation. Typically, leaving about a quarter to half an inch of the bolt above the nut is sufficient for a secure fit and a neat appearance.

Mark the cutting point on each bolt with a pencil or marker. Double-check your measurements to confirm that the marking is in the correct position, as cutting the bolts too short could compromise the stability of the toilet. Taking the time to measure accurately will ensure a smooth installation process and avoid the need for additional adjustments.

Step 4: Secure the Bolt in Place

To prevent the bolt from moving around while cutting, secure it in place using a vice or clamp. This will give you more control over the cutting process and reduce the risk of injury.

Before securing the bolt, wrap a cloth or tape around it to protect its surface from scratches or damage from the vise’s grip. Make sure the bolt is firmly held in place before proceeding with cutting.

Step 5: Cut Carefully

Using your hacksaw, carefully cut through the marked point on each bolt. Hold the saw at a slight angle for better control and start slowly to ensure an accurate cut. Apply gentle pressure and use long, smooth strokes to avoid damaging or warping the bolt. Stop periodically to check your progress and adjust if needed until you have cut through the bolts completely.

It is always better to cut less initially and make additional cuts if needed rather than cutting too much off at once. This will help prevent any mistakes or issues with the bolt length.

Step 6: File Down Any Rough Edges

After cutting the bolts, it’s essential to smooth out any rough or sharp edges left behind. Use a metal file to gently file down the cut edges, ensuring they are smooth and free of burrs. This step prevents potential injuries during installation and ensures that the nuts can be easily threaded back onto the bolts without resistance.

Hold the file at a slight angle and work in one direction for consistent results. Check the edges periodically by running your gloved hand over them to feel for any remaining rough spots. Once the edges are smooth, clean away any metal shavings or debris with a cloth to keep the installation area tidy and safe.

Step 7: Reattach the Nuts and Washers

After cutting and filing down the bolts, it is time to reattach the nuts and washers. Start by threading each nut onto its respective bolt, followed by a washer. Carefully tighten the nuts using your adjustable wrench clockwise until they are firmly secured against the toilet base.

Be careful not to overtighten, as this could damage or break the bolts. If you have difficulty tightening the nuts, it may be necessary to use a pair of pliers for extra torque. Once tightened, check for any movement or wobbling of the toilet to ensure a stable installation.

Step 8: Test Your Work

Before placing any weight on the toilet, test your work by pushing down gently on the seat. If there is no movement or wobbling of the toilet, your installation was successful. If you notice any instability, double-check that the bolts are securely tightened and make adjustments if needed.

With proper cutting and installation of the toilet bolts, you can now proceed with installing the wax ring and reattaching the water supply line to complete your toilet installation successfully.

Following these step-by-step instructions on how to cut toilet bolts and taking the time to accurately measure, cut, and install the toilet bolts will ensure a secure and stable installation. Always take necessary precautions such as wearing safety glasses and gloves when handling tools, and remember to file down any rough edges for a clean finish. Congratulations on a job well done! Happy DIY-ing!

Additional Tips

- If you have access to a reciprocating saw or rotary tool with a metal cutting blade, they can also be used t to cut toilet bolts quickly and efficiently.

- If your toilet is placed against a wall, you may need to use a hacksaw blade with an adjustable handle for better maneuverability.

- It is always recommended to have someone assist you when cutting the bolts to hold the vise or clamp in place while you cut. This will ensure stability and reduce the risk of injury.

- Remember to dispose of any leftover pieces of cut bolts properly and clean up the area before proceeding with installation. Safety first!

Frequently Asked Questions

Q1: Can I Use a Regular Saw to Cut Toilet Bolts?

A: While it is possible to use a regular saw, it is not recommended. Regular saws are designed for cutting wood and may cause the bolt to bend or warp, making it difficult to install. Hacksaws or rotary tools with metal blades are more suitable for cutting toilet bolts.

Q2: Can I Reuse Cut Toilet Bolts?

A: Reusing cut toilet bolts is not recommended, as they may have been weakened during the cutting process and could compromise the stability of the toilet.

Q3: How Do I Know If The Bolts Are Too Short To Use?

A: One way to determine if the bolts are too short is by checking for any movement or wobbling of the toilet after installation. If there is noticeable movement, it may be necessary to purchase longer bolts and start again. It is always better to err on the side of caution when measuring and cutting toilet bolts.

Conclusion

Cutting toilet bolts may seem like a daunting task, but by following these step-by-step instructions and using the right tools, it can be done easily and safely. Remember to always measure accurately, use protective gear, and take your time to ensure a successful and stable installation.

With these tips and techniques on how to cut toilet bolts, you can confidently tackle any DIY project that involves cutting toilet bolts. Happy DIY-ing!