Are you tired of constantly replacing your toilet flapper? Are you looking for ways to extend its lifespan and save money in the long run? Look no further, as we have compiled a list of tips and tricks to help you prolong the lifespan of your toilet flapper.

Keeping your toilet in order can save you time, money, and frustration. One crucial component often overlooked is the toilet flapper—a small but essential part that controls water flow from the tank to the bowl. When properly maintained, a toilet flapper can last for years, ensuring your toilet functions efficiently and preventing water wastage.

This guide will provide practical tips and strategies on how to extend the lifespan of a toilet flapper, avoiding frequent replacements and improving your plumbing system’s overall durability.

What Are the Causes of a Short Toilet Flapper Lifespan?

Before we jump into the tips and tricks, we must understand why toilet flappers have a short lifespan. The following are some common causes:

- Mineral Buildup: Hard water contains high minerals that can accumulate on the toilet flapper over time. This buildup can cause the flapper to become stiff and less flexible, leading to early wear and tear.

- Chemical Damage: Harsh chemicals commonly used in cleaning products can also damage the rubber material of the flapper.

- Constant Use: Frequent flushing throughout the day can strain the flapper excessively, causing it to wear out quickly.

Now that we know some reasons for a short toilet flapper lifespan let’s look at some practical ways to extend it.

What Will You Need?

You don’t need any special tools or equipment to extend your toilet flapper’s lifespan. Here are some items you may need:

- A clean rag

- White vinegar

- Baking soda

Once you have these items on hand, you are ready to start extending the lifespan of your toilet flapper.

9 Easy Steps on How to Extend the Lifespan of a Toilet Flapper

Step 1. Turn Off the Water Supply:

Locate the shut-off valve near the base of your toilet, typically on the wall or floor behind the toilet bowl. Turn the valve clockwise until it stops, ensuring the water flow to the toilet is completely cut off. This step is crucial to prevent water from continuously flowing into the tank while you’re working on the flapper. Once the water supply is turned off, flush the toilet to drain the water from the tank.

This will allow you to access the flapper easily and work on cleaning or maintenance without dealing with excess water. Double-check that the tank is empty before proceeding to the next steps.

Step 2. Remove the Toilet Tank Lid:

Carefully lift the lid off the toilet tank and set it aside safely, preferably on a flat surface, to prevent it from tipping or breaking. Toilet tank lids are often made of fragile porcelain, which can crack or chip easily if mishandled. Be sure to use both hands when lifting to maintain a secure grip. Also, don’t bump the lid against other bathroom fixtures or walls. This step allows you to gain full access to the tank’s internal components, including the flapper, which is essential for completing any maintenance or cleaning.

Take a moment to visually inspect the inside of the tank for any obvious issues before proceeding.

Step 3. Inspect the Flapper:

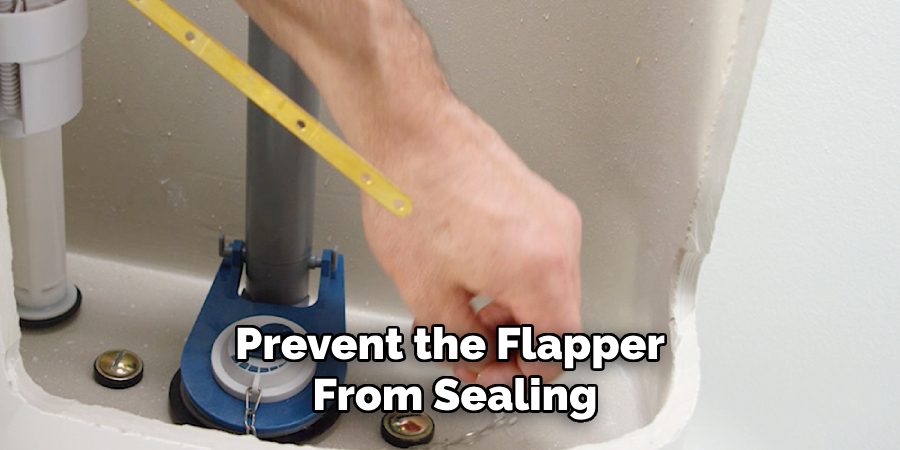

Locate the flapper at the bottom of the toilet tank, typically a rubber or plastic component connected to the flush handle by a chain. Examine it closely for any signs of wear, such as cracks, tears, or warping, as these can cause leaks or improper flushing. If the flapper appears dirty, it is essential to clean it—using a soft brush and warm, soapy water often works well to remove any buildup or residue.

If the flapper shows significant damage, it may need to be replaced to ensure optimal performance. Take care not to dislodge or tangle the chain in the process accidentally.

Step 4. Check the Flush Valve Seat:

With the flapper inspected and cleaned or replaced if necessary, take a close look at the flush valve seat, which is the area where the flapper creates a seal to prevent water from leaking into the bowl. Inspect this surface for any signs of damage, such as cracks, corrosion, or debris buildup. Use a soft cloth or sponge to clean the valve seat thoroughly, ensuring that no obstructions remain that could prevent the flapper from sealing correctly.

If the flush valve seat is damaged beyond repair, consider replacing it to restore the toilet’s functionality and prevent ongoing issues.

Step 5. Inspect the Fill Valve:

The fill valve is a crucial component of the toilet’s tank and is responsible for refilling the tank after each flush. Begin by checking the fill valve for any signs of wear or malfunction, such as inconsistent water flow or strange noises during operation. Ensure that the float mechanism is adjusted correctly and moves freely without sticking. Clean the fill valve with a soft brush to remove any mineral deposits or debris if necessary.

Should the fill valve be damaged or not functioning correctly, replacing it with a compatible part can help resolve water-filling issues and improve the toilet’s overall performance.

Step 6. Examine the Flush Handle and Chain:

The flush handle and chain play a vital role in initiating the flushing process by lifting the flapper from the valve seat. Inspect the flush handle to ensure it moves freely and is not loose or corroded. Next, check the chain connected to the handle and the flapper, ensuring it has the proper slack—not too tight, preventing the flapper from fully closing and not too loose, which can hinder the flushing action.

If necessary, adjust the chain length or replace it if it appears worn or damaged. Properly functioning handle and chain mechanisms ensure a consistent and efficient flush.

Step 7. Inspect the Flapper:

The flapper is a crucial component of the toilet’s flushing system, sealing the tank and controlling the release of water during a flush. Start by carefully inspecting the flapper for any signs of wear, warping, or buildup of mineral deposits, which could prevent it from creating a proper seal. A deteriorated or damaged flapper can cause continuous water leakage into the bowl, leading to higher water bills.

Clean the flapper with a gentle solution to remove any buildup, or if it is too worn, replace it with a compatible part. Ensuring the flapper is in good condition is vital for maintaining the efficiency of the toilet’s flushing system.

Step 8. Keep the Toilet Tank Clean:

Regularly cleaning your toilet tank can help prevent issues with the flapper and other internal components. Use a gentle cleaner or a mixture of vinegar and baking soda to remove any mineral deposits or buildup that could affect the function of the flapper and other parts. Avoid using harsh chemicals, as they can cause damage to the inner workings of the tank. A clean tank also helps maintain a more hygienic bathroom environment.

Step 9. Turn On the Water Supply and Test:

After cleaning or replacing any components in the toilet tank, the next step is to turn the water supply back on. Locate the water shut-off valve near the toilet’s base and slowly turn it counterclockwise to allow water to flow into the tank. Monitor the water level as the tank fills to ensure it reaches the appropriate line, typically marked on the inner wall of the tank or as indicated in your toilet’s manual.

Test the flushing mechanism once the tank is complete by pressing the flush handle or button. Observe the water movement to ensure the flapper seals correctly and that there is no leakage between the tank and bowl. Check for any unusual sounds or irregularities, such as weak flushing or slow tank refilling, as these could indicate additional issues that need attention. Repeat the test a few times to confirm all components are functioning smoothly.

By following these steps and regularly maintaining your toilet tank, you can ensure optimal performance and prevent potential issues that could lead to costly repairs in the future.

5 Things You Should Avoid

- Using Harsh Cleaning Chemicals: Avoid using strong chemical cleaners in your toilet tank, such as bleach or acidic solutions. These chemicals can degrade the material of the flapper, causing it to harden or crack prematurely.

- Flushing Non-Biodegradable Items: Do not flush items like wipes, feminine hygiene products, or paper towels. These can lead to clogs that strain the flushing mechanism, indirectly affecting the flapper’s lifespan.

- Neglecting Regular Maintenance: Skipping routine inspections and cleaning of the tank can lead to mineral buildup or debris around the flapper, reducing its effectiveness and shortening its life.

- Ignoring Leaks: If water is constantly running or leaking into the bowl, address the issue immediately. Ignoring leaks forces the flapper to work overtime, causing unnecessary wear and tear.

- Using an Ill-Fitted Flapper: Ensure you use a flapper compatible with your toilet model. An ill-fitting flapper can fail to seal correctly, leading to leaks and faster deterioration.

Conclusion

How to extend the lifespan of a toilet flapper is a straightforward process that revolves around proper care and maintenance.

Regularly inspect and clean the flapper and surrounding tank components to prevent mineral buildup and debris from affecting its functionality. Use only toilet-safe cleaning agents to avoid damaging the flapper’s material. Always ensure that the flapper fits appropriately and is compatible with your toilet model, as this prevents leaks and ensures a secure seal. Lastly, any leaks or mechanical issues should be promptly addressed to avoid unnecessary strain on the flapper.

By following these simple steps, you can significantly prolong the life of your toilet flapper and maintain a properly functioning toilet system.