Are you wondering how to install a toilet flange on concrete? Look no further, as we have all the information you need right here!

Installing a toilet flange on a concrete floor might seem intimidating, but with the right tools and guidance, it can be completed efficiently. The toilet flange plays a crucial role in securing the toilet to the floor and connecting it to the waste pipe for proper drainage. Whether working on a new installation or replacing an old flange, following the proper steps is important to ensure a solid and leak-free connection.

This guide will walk you through the process, providing clear instructions to help you achieve a professional result, even if tackling this as a DIY project.

What Will You Need?

Before you can install a toilet flange, you will need to gather the necessary tools and materials. Here are some of the items that may be required:

- Toilet Flange: This is typically made of PVC or cast iron and comes in different sizes to fit your waste pipe.

- Wax Ring or Gasket: A wax ring is the traditional choice for creating a tight seal between the flange and toilet base. However, a rubber gasket can also be used as an alternative.

- Toilet Bolts: These are needed to secure the toilet to the flange.

- Adjustable Wrench: This tool will help tighten bolts and nuts during installation.

- Screwdriver: You may need this to remove the old toilet and to tighten screws or bolts.

- Plunger: This will be useful if you encounter any clogs during installation.

Once you have gathered all necessary materials and tools, it’s time to begin the installation process.

9 Easy Steps on How to Install a Toilet Flange on Concrete

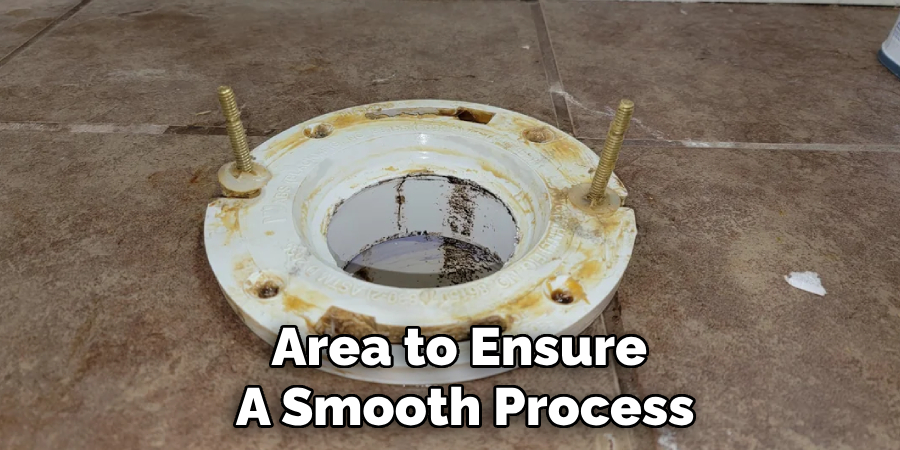

Step 1: Prepare the Area

Before you start installing the toilet flange, it’s essential to prepare the area to ensure a smooth process. Begin by turning off the water supply to the toilet. You can do this by locating the shut-off valve near the base of the bathroom and twisting it clockwise until it is fully closed. Next, flush the toilet to remove as much water as possible from the tank and bowl. Use a sponge or a towel to soak up any remaining water in the tank and bowl to prevent spills during removal.

Once the toilet is dry, use a utility knife to cut any caulking or sealant around its base. Carefully lift and remove the old toilet, ensuring you have a place to set it down, such as a piece of cardboard or an old towel, to prevent damage to the floor. If the wax ring from the previous installation is still present, use a putty knife to scrape it away thoroughly.

Step 2: Measure and Choose the Flange

The flange is a crucial component in the toilet installation process as it connects the toilet to the plumbing system while securing it to the floor. Begin by inspecting the condition of the existing flange to determine if it is reusable. If it’s cracked, corroded, or otherwise damaged, replacing it before proceeding with the installation is essential. Measure the diameter of the drainpipe and the existing bolt spacing to ensure compatibility with the new flange.

Flanges typically come in different materials such as PVC, ABS, or metal, so select a durable flange suitable for your plumbing configuration. Adjustable flanges are also available, which can help compensate for slight alignment issues or uneven flooring. Additionally, consider the flange height—ideally, it should sit level with or slightly above the finished flooring to create a proper seal with the toilet.

Step 3: Mark the Flange Placement

To ensure accurate installation, carefully measure and mark the placement of the flange before proceeding. Begin by identifying the center of the drainpipe opening, as this is where the flange will align. Use a pencil or marker to outline the flange’s base on the subfloor, ensuring that it is positioned evenly and centered with the intended location of the toilet.

Double-check the alignment with the surrounding area and take note of any adjustments needed due to uneven surfaces or obstacles. For bathrooms with tiled or finished flooring, ensure the flange placement does not disrupt the flooring integrity by confirming that any cuts or holes are precise.

Step 4: Drill Pilot Holes

Using the previously marked outline as a guide, prepare to secure the flange to the subfloor by drilling pilot holes. Pilot holes are essential for ensuring that screws or bolts can be driven into place with ease and without causing damage to the surrounding materials.

Begin by selecting a drill bit that matches the size of the screws you plan to use, ensuring it is slightly smaller than the screws’ diameter to provide a snug and secure fit. Carefully position the drill at each marked hole location on the flange and begin drilling straight down into the subfloor.

Step 5: Anchor the Flange

Once the pilot holes have been successfully drilled, the next step is to anchor the flange to the subfloor securely. To do this, position the flange over the drilled pilot holes, ensuring that it is properly aligned and sits flush against the subfloor surface. Use screws or bolts that are appropriate for the flange material and the subfloor type.

Begin inserting the screws or bolts into each of the pilot holes, tightening them evenly around the flange to avoid creating any imbalance or gaps. Take care not to overtighten, as this can damage the flange or the surrounding subfloor, compromising the stability of the installation. For added security, you may choose to apply a thin layer of construction adhesive to the bottom of the flange before securing it with screws or bolts.

Step 6: Attach the Wax Ring

The wax ring is crucial as it creates a watertight seal between the toilet and the flange, preventing leaks and unpleasant odors from escaping. Begin by selecting the appropriate wax ring for your toilet model and flange type—standard rings work well for most installations, but thicker wax rings may be necessary if the flange sits lower than the finished floor.

Carefully place the wax ring onto the toilet bowl outlet or directly onto the flange, depending on your preference or the manufacturer’s instructions. Make sure it is centered to ensure an even and effective seal. Avoid pressing or disturbing the wax ring excessively, as this can compromise its integrity, leading to potential issues.

Step 7: Position the Toilet

With the wax ring securely in place, carefully lift the toilet bowl and position it over the flange. Align the bolts extending from the flange with the holes on the toilet’s base. Lowering the toilet straight down onto the wax ring is essential to avoid shifting or misalignment, which could compromise the seal.

Once the bathroom is resting, gently press down to compress the wax ring and ensure a tight seal between the bowl and the flange. Avoid rocking or twisting the toilet, as this could displace the wax ring or cause uneven pressure. Take a moment to visually check the alignment and ensure the toilet is level before proceeding to the next step.

Step 8: Secure the Toilet

Once the toilet is aligned correctly and sitting level, it’s time to secure it to the floor. Begin by threading the nuts onto the mounting bolts on either side of the toilet base. Tighten the nuts gradually, alternating between the two sides as you go to ensure even pressure and prevent cracking the porcelain.

Use a wrench or pliers to tighten the nuts snugly, but be careful not to overtighten, as this could damage the toilet or distort its alignment. Once the nuts are securely fastened, inspect the connection to ensure the toilet is firmly held, with no rocking or movement.

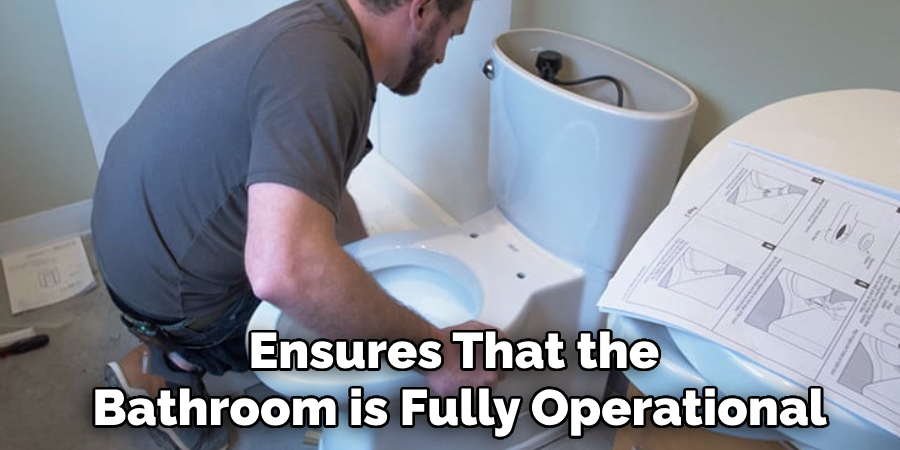

Step 9: Reconnect the Water Supply

To reconnect the water supply, first locate the supply hose that was previously detached. Align the threaded end of the hose with the fill valve on the base of the toilet tank. Carefully screw the hose onto the fill valve by hand, turning it clockwise until it is hand-tight. Once secure, use an adjustable wrench to give it a final gentle turn to ensure the connection is firm, but avoid overtightening as this could damage the threads or cause leaks.

After the hose is connected, turn the water supply valve near the wall back on by turning it counterclockwise. Allow the water to flow into the toilet tank, and watch carefully for signs of leaks around the hose connection. If a leak occurs, turn off the water supply and check the tightness of the connection. Once the tank has filled, flush the toilet a few times to ensure that the water refills properly and no leaks are present. This process ensures that the bathroom is fully operational and ready for use.

By following these steps, you can successfully install a toilet flange on concrete, ensuring a secure and professional result.

Conclusion

How to install a toilet flange on concrete may seem challenging at first, but with the right tools, materials, and careful attention to detail, it can be completed effectively.

You can achieve a functional and durable installation by adequately preparing the surface, securing the flange, and ensuring all connections are tight and leak-free. Taking the time to follow each step thoroughly will save you from potential issues down the line and provide peace of mind knowing the job has been done correctly.

Hopefully, this guide has given you a better understanding of installing and connecting a toilet to concrete.