Are you tired of hearing your toilet running all night long? Or perhaps you’ve noticed that it takes longer than usual for your tank to fill after flushing. It could be time to replace your toilet fill valve.

Installing a toilet fill valve is a relatively simple and cost-effective way to fix common toilet issues, such as constant running water, weak flushing, or noisy refills. The fill valve controls water flow into the toilet tank and ensures it refills to the proper level after each flush. Replacing or installing a new fill valve can restore your toilet’s functionality and improve its efficiency.

This guide on how to install toilet fill valve will walk you through the essential steps to install a toilet fill valve, even if you are new to DIY plumbing projects.

What Are the Benefits of Installing a Toilet Fill Valve?

Replacing or installing a new toilet fill valve can benefit your bathroom and household. Some of these advantages include:

- Improved Flushing Performance: A properly functioning fill valve ensures that the tank is filled with the right amount of water for an efficient flush every time.

- Reduced Water Waste: A faulty fill valve can cause constant water running, which wastes water and raises utility bills. Installing a new fill valve can help conserve water and save money in the long run.

- Quieter Operation: When refilling the tank after each flush, old or malfunctioning fill valves can be noisy. By replacing them, you can enjoy a quieter bathroom experience.

- Prevents Potential Leaks: A damaged or worn-out fill valve can lead to leaks in the toilet, which not only waste water but can also damage your bathroom floor. Installing a new fill valve can prevent these potential leaks and save you from costly repairs in the future.

What Will You Need?

To replace a fill valve, you will need the following tools and materials:

- New fill valve kit (available at most hardware stores)

- Adjustable wrench or pliers

- A bucket or a towel to catch any excess water

- Flush valve gasket (optional)

- Safety glasses (recommended)

Once you have all the necessary materials, you can begin the process of replacing your fill valve.

10 Easy Steps on How to Install Toilet Fill Valve

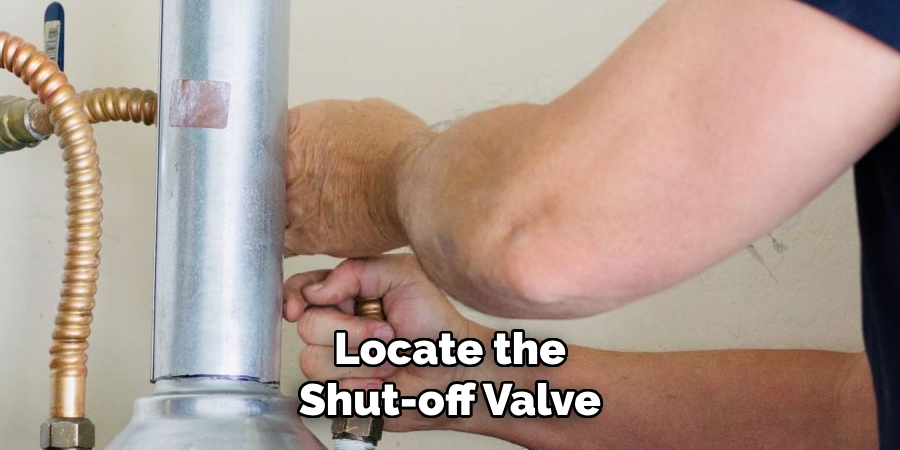

Step 1: Turn Off the Water Supply

Locate the shut-off valve for your toilet, which is typically found on the wall or floor behind the toilet. Turn the valve clockwise until it is fully closed to stop the water flow. To ensure the water supply is completely turned off, flush the toilet and check if the tank empties. Place a bucket or towel under the tank to catch any remaining water. Properly shutting off the water supply will prevent leaks and simplify the replacement process.

Step 2: Disconnect the Water Supply Line

To disconnect the water supply line, locate the hose connecting the toilet tank to the valve. Use an adjustable wrench or a pair of pliers to carefully loosen the nut that secures the hose to the fill valve at the bottom of the tank. Turn the nut counterclockwise until it is fully detached. Have a bucket or towel ready to catch any excess water that may drain from the hose. Once the line is completely disconnected, set it aside, ensuring it is out of the way for the next steps.

Step 3: Remove the Old Fill Valve

With the water supply line disconnected, locate the lock nut on the underside of the toilet tank that secures the fill valve in place. Use an adjustable wrench or your hands to loosen and remove the lock nut by turning it counterclockwise. Once the nut is fully removed, carefully lift the old fill valve out of the tank. Be cautious to avoid damaging any internal components or surrounding parts. Set the old fill valve aside for proper disposal, and take this opportunity to clean any debris or residue from the area where the new fill valve will be installed.

Step 4: Clean the Tank Opening

Before installing the new fill valve, thoroughly clean the area around the tank opening. Use a cloth or sponge to remove debris, residue, or sediment buildup. This step is crucial to create a proper seal and to ensure the new fill valve fits securely. Pay special attention to the edges of the opening and confirm no obstructions might interfere with the installation. A clean surface will help prevent leaks and guarantee optimal performance of the new fill valve.

Step 5: Prepare the New Fill Valve

Carefully unpack the new fill valve and check that all components are included, such as washers, locking nuts, and any additional fittings specified in the instructions. Adjust the height of the fill valve according to your tank’s specifications, ensuring it matches the required water level. Most fill valves have an adjustable stem that can be twisted or extended to the correct height.

Attach the rubber washer or gasket to the base of the fill valve to create a watertight seal. Double-check the manufacturer’s instructions for specific preparation steps to ensure proper installation.

Step 6: Install the New Fill Valve

Position the new fill valve inside the tank, ensuring the base of the valve fits securely into the hole at the bottom of the tank. Insert the threaded end of the valve through the hole, and from underneath the tank, secure it in place using the lock nut. Tighten the nut by hand to avoid overtightening, which could crack the tank.

Once the fill valve is secured, reconnect the water supply line to the base of the valve. Use a wrench to tighten the connection, ensuring there are no leaks, gently. Finally, verify the alignment of the fill valve, keeping it upright to ensure proper operation.

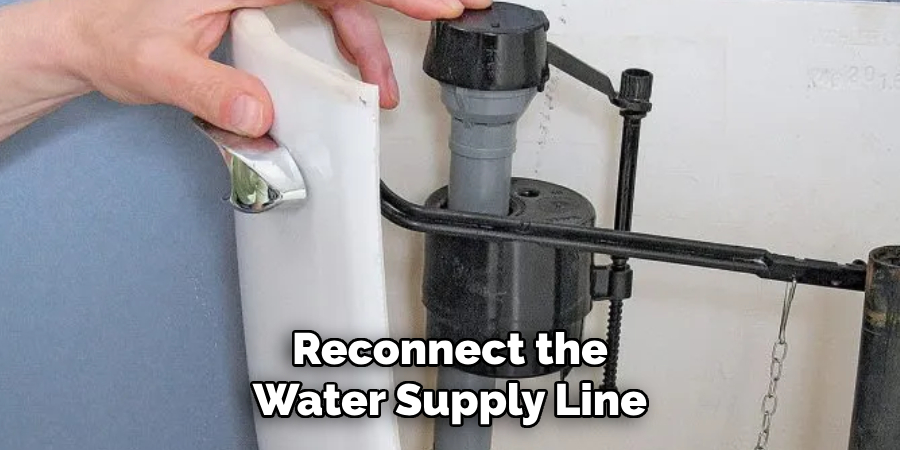

Step 7: Reconnect the Water Supply Line

After securing the fill valve in place, it’s time to reconnect the water supply line. Begin by aligning the supply line’s coupling nut with the fill valve’s base. Thread the nut onto the valve by hand, turning it clockwise until it’s snug. Once hand-tightened, use an adjustable wrench to give it an additional quarter-turn to ensure a secure connection.

Be cautious not to overtighten, as this could damage the fittings or cause leaks. Once the connection is secure, turn the water supply back on slowly, allowing the tank to fill while checking for any signs of leakage at the connection point. If a leak is detected, gently tighten the coupling nut further.

Step 8: Refill the Tank

After ensuring the connection is secure, carefully open the shut-off valve to allow the water to refill the tank. Monitor the refilling process to confirm that the water flows smoothly and the float mechanism works properly. Check the water level once the tank is full to ensure it meets the manufacturer’s recommended fill line, typically marked inside the tank. If adjustments are necessary, use the float adjustment screw to set the water level correctly. Finally, flush the toilet to confirm that everything functions as expected and there are no leaks or irregularities.

Step 9: Adjust the Water Level

Adjusting the water level is critical to ensure the toilet operates efficiently without wasting water. Begin by identifying the float adjustment screw, typically located on the top of the fill valve assembly. Using a screwdriver, turn the screw clockwise to raise the water level or counterclockwise to lower it, depending on the need. Make minor adjustments and check the water level after each turn to avoid overcorrecting.

The goal is to align the water level with the fill line indicated inside the tank. If there is no visible fill line, refer to the toilet manufacturer’s proper water level height guidelines. Once adjusted, flush the toilet again to ensure the water reaches the ideal level and verify that no water continues to run into the bowl after the tank has refilled.

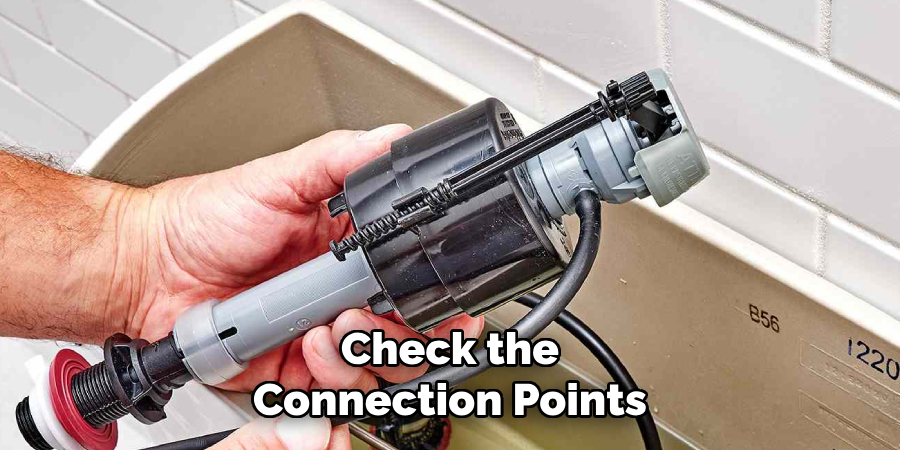

Step 10: Test the New Fill Valve

To test the newly installed fill valve, flush the toilet and observe its operation closely. Ensure the tank refills efficiently and stops at the desired water level without overfilling. Listen for any unusual noises or signs of continuous water flow, as this could indicate a need for further adjustments. Additionally, check the connection points for any potential leaks. If everything functions correctly, the installation is complete, and your fill valve is ready for use.

By following these steps, you can effectively replace your toilet’s fill valve and restore its functionality. Proper installation ensures your toilet operates efficiently and can prevent further issues.

Conclusion

How to install toilet fill valve may seem daunting at first, but with the right tools and step-by-step guidance, it becomes a manageable task for any homeowner.

You can ensure your toilet operates smoothly by carefully removing the old fill valve, securely installing the new one, and thoroughly checking for leaks or malfunctions. Taking the time to perform this repair yourself not only saves money but also empowers you with valuable DIY skills.

Remember always to follow the manufacturer’s instructions and double-check your work for a successful installation.