Are you tired of dealing with a glued-in toilet flange? Don’t worry—you are not alone.

How to remove glued in toilet flange can seem like a daunting task, but with the right tools and approach, it can be managed effectively. A toilet flange is crucial to your plumbing system, securing the toilet to the floor and connecting it to the drain pipe. Over time, it may need to be replaced due to damage or wear. Since some flanges are glued into place, removing them requires proper preparation and technique to avoid damaging the surrounding plumbing.

This guide will walk you through the steps to carefully and successfully remove a glued-in toilet flange, ensuring your plumbing system remains intact and functional.

What Are the Causes of Damage to Toilet Flanges?

Toilet flanges can become damaged for various reasons, including the age and quality of the materials used, improper installation, and wear and tear over time. Some common causes of damage include:

- Corrosion: If the flange is made of metal, it may corrode over time due to exposure to moisture and other elements.

- Cracking: Plastic or PVC flanges can crack if not correctly installed or if excessive force is applied during use.

- Warping: Flanges of any material can warp if exposed to high heat or pressure.

- Loose Bolts: Over time, the bolts that secure the toilet to the flange can become loose, causing the flange to shift and potentially break.

- Rust: Metal bolts used to secure the toilet to the flange can rust and weaken over time.

- Age: Like all plumbing system components, flanges will naturally deteriorate with age.

In addition to these common causes, accidents or improper installation can also damage or fail a toilet flange to fail.

What Will You Need?

To replace a damaged or broken toilet flange, you will need some basic tools and materials. These include:

- New Toilet Flange: You will need to purchase a new toilet flange compatible with your existing plumbing system. Various types of flanges are available, including PVC, cast iron, and stainless steel.

- Screwdriver: Depending on the type of bolts used to secure the toilet to the flange, you may need either a screwdriver or wrench (or both) to loosen and remove them.

- Putty Knife: This tool can be helpful in scraping away any old wax or sealant around the toilet’s base before installing the new flange.

- Plumber’s Putty: This is a waterproof sealant that creates a tight seal between the toilet and the flange. It is typically applied to the base of the toilet before being placed on the flange.

- Plunger: If your plumbing system has clogs or blockages, having a plunger on hand can help resolve these issues quickly.

8 Easy Steps on How to Remove Glued in Toilet Flange

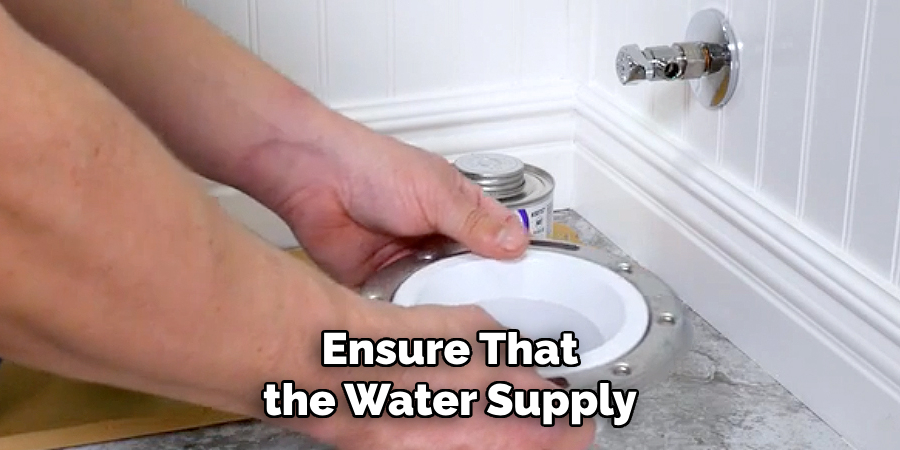

Step 1. Turn Off the Water Supply

Before starting, ensure that the water supply to the toilet is completely turned off. Locate the water shut-off valve on the wall near the toilet’s base, and turn it clockwise until it is fully closed. This is a crucial step to prevent water from flooding your bathroom. Once the water is turned off, flush the toilet to drain the tank and bowl of any residual water. You may need to use a sponge or a wet/dry vacuum to delete any remaining water. Taking this precaution will make the task cleaner and more manageable.

Step 2. Disconnect the Toilet

To disconnect the toilet, start by removing the caps covering the bolts at the base using a flathead screwdriver. Once the caps are removed, use an adjustable wrench to loosen and unfasten the nuts securing the toilet to the floor. Carefully set the nuts and washers aside to avoid losing them.

Next, disconnect the water supply line from the base of the toilet tank by unscrewing it with an adjustable wrench. Be prepared for a small amount of water to spill from the line, so keep a bucket or towel handy. Once these connections are undone, gently rock the toilet back and forth to break the wax seal at the base, then lift the toilet straight up and place it on a prepared surface, such as cardboard or an old towel, to avoid damaging your flooring.

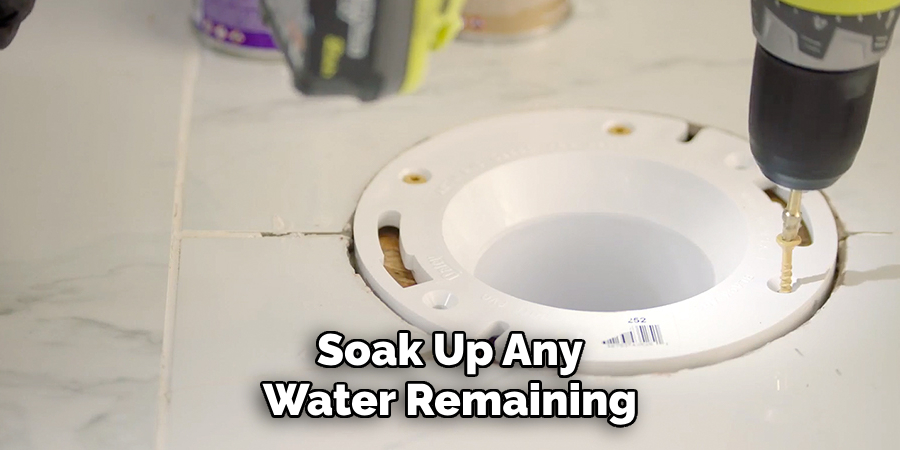

Step 3. Clean Up Residual Water

Use a sponge or a small towel to soak up any water remaining in the plumbing or around the base of the toilet flange. Check the flange for any dampness or debris and carefully wipe it clean. If any old wax residue is left on the flange, use a putty knife to scrape it off gently, ensuring the surface is smooth and ready for the new wax ring installation. Properly cleaning this area ensures a secure and leak-free connection for the new toilet. Dispose of the old wax ring and any waste materials appropriately.

Step 4. Loosen the Flange

If the toilet flange is secured tightly, you may need to loosen it to adjust or replace it properly. Start by examining the screws or bolts holding the flange in place. Use a screwdriver or a wrench to carefully loosen these fasteners, turning them counterclockwise. Do not apply excessive force, as this could damage the flange or surrounding plumbing. If the screws are corroded or difficult to turn, use a penetrating oil and wait a few minutes to ease the process. Once the flange is loosened, you can adjust its position or remove it entirely if a replacement is needed.

Step 5. Apply Heat to the Flange

Applying heat to the flange can help loosen it, especially if it is stuck due to corrosion or old sealant. Use a heat gun, set to a moderate temperature, and direct the heat evenly around the flange. Keep the heat source moving to avoid overheating or damaging the material. If you do not have a heat gun, a hairdryer on its highest setting can be an alternative. Be cautious when using heat near flammable materials or in enclosed spaces. After a few minutes of heating, try loosening the flange again with your tools, as the heat will have helped expand the metal or soften the sealant, making removal easier.

Step 6. Cut the Flange

If the flange still cannot be removed after applying heat, cutting it may be the most effective solution. Begin by selecting the appropriate cutting tool for the material of the flange. A hacksaw, angle grinder, or reciprocating saw equipped with a metal-cutting blade is ideal for metal flanges. A handsaw or specialty pipe cutter may work better for plastic or PVC flanges. Before you start cutting, ensure the surrounding area is clear of any obstacles or sensitive components to prevent accidental damage.

Wear protective equipment such as gloves, safety glasses, and a dust mask to shield yourself from sharp debris or fine particles. Carefully make controlled cuts into the flange, keeping your cuts straight and avoiding cutting into the surrounding surface. Once the desired cuts have been made, use a file or sandpaper to smooth out any rough edges and ensure a clean fit for the new pipe.

Step 7. Pry Off the Flange

Using a pry bar or a flathead screwdriver, carefully work around the edges of the flange to loosen it. Apply gradual, even pressure to avoid bending or damaging the surrounding area. If the flange proves stubborn, gently tap the tool with a mallet to help break it free. Be cautious of any sharp edges or remaining fasteners that may still be attached, and ensure the flange is completely detached before proceeding. Once removed, inspect the underlying surface for any signs of corrosion, debris, or damage, and clean or repair the area as needed to ensure a proper seal when the new flange is installed.

Step 8. Remove Old Adhesive

Remove any old adhesive or sealant left on the surface from the previous installation using a scraper or putty knife. Be sure to work methodically to avoid scratching or damaging the underlying surface. For particularly stubborn adhesive, consider using a heat gun at a low setting to soften the material, making it easier to scrape away. Alternatively, an adhesive remover solution can help break down tougher residues.

After removing the bulk of the adhesive, wipe the surface with a clean cloth and a suitable solvent to eliminate any remaining traces. It’s crucial to ensure the surface is spotless, smooth, and residue-free to provide an optimal bonding area for the new flange and to prevent future leaks or installation issues. Take your time during this step, as a properly prepared surface will contribute to the longevity and effectiveness of the repair or replacement.

Following these steps will help ensure the safe and effective removal of a glued-in toilet flange, allowing you to proceed with any necessary repairs or replacements.

Conclusion

How to remove glued in toilet flange may seem like a daunting task, but with proper preparation, the right tools, and careful execution, it can be successfully achieved.

Following the outlined steps, you can remove the old flange without causing unnecessary damage to the surrounding plumbing or flooring. Always prioritize safety and patience to achieve a clean surface, allowing for a secure and leak-free installation of the new flange.

With attention to detail and a methodical approach, you can complete the task effectively and restore proper functionality to your plumbing system.