Do you own a Sloan Flushmate toilet? Over time, the internal components of your Sloan Flushmate can become worn or damaged, leading to a loss of flush power. To keep your Sloan Flushmate functioning at its best, it’s important to inspect and repair any issues quickly.

In this blog post, we’ll provide an overview of how to determine if your Sloan Flushmate needs repairs, plus helpful tips on how to repair sloan flushmate toilet yourself—allowing you to save money and get back to enjoying the powerful flushes offered by this reliable toilet system. Read on for our guide on diagnosing and repairing common problems with a Sloan Flushmate unit!

Step-by-step Guidelines on How to Repair Sloan Flushmate Toilet

Step 1: Check the Flushmate System for Leaks

First things first, you’ll want to check for visible signs of leaking or water damage. Check the exterior of the Sloan Flushmate unit and its connecting pipes for any signs of water pooling or dripping. If you find that there is a leak, this could indicate a problem with the Sloan Flushmate’s internal components, such as a damaged or worn seal.

Step 2: Examine the Float Ball and Chain Assembly

Next, take a look at the float ball and chain assembly. If it appears rusty or corroded, this could be an indication of an issue with the Sloan Flushmate’s water supply or interior components. You may need to replace the entire assembly if it’s too far gone. If the assembly looks in good shape, you can try cleaning it to remove any debris that may have collected and is preventing it from functioning properly.

Step 3: Inspect the Fill Valve and Flush Valve

You should also inspect the fill valve and flush valve to ensure they are clean and fully functional. If either of the valves is blocked, it could cause a decrease in flush power. You should also check for any signs of corrosion or wear on the valves. It may be necessary to replace the valves if they are too far gone.

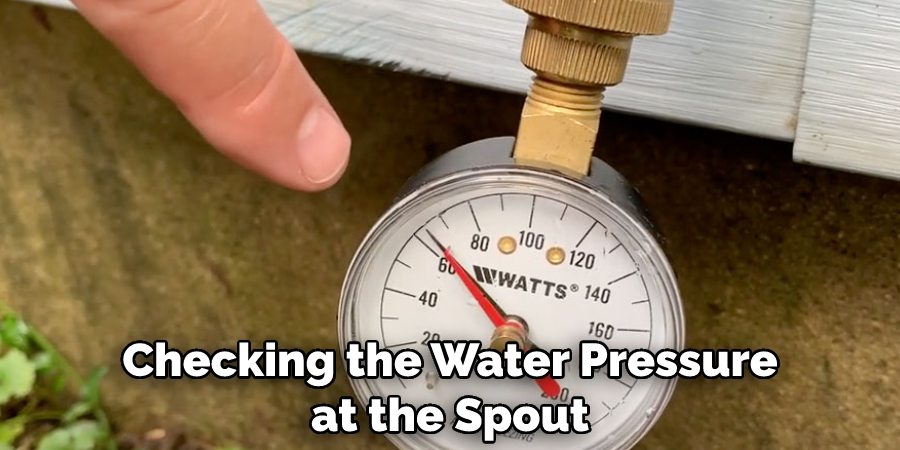

Step 4: Test Water Pressure at the Spout

Another simple test you can perform is checking the water pressure at the spout. Turn on your sink faucet and measure how much water comes out when you open it all the way—this will tell you if there’s an issue with your home’s water pressure. You can use a digital pressure gauge or purchase a water pressure testing kit to get an accurate reading.

Step 5: Check for Blockages in Your Pipes

Inspect the pipes that connect to your Sloan Flushmate for any blockages or clogs. If you find a clog, use a plunger or snake to remove it and restore normal water flow. You may also need to flush out the pipes with a hose. That’s it—your Sloan Flushmate should now be functioning properly again.

Step 6: Look for Signs of Wear on Your Toilet Tank Gasket

Over time, the toilet tank gasket can become worn due to regular use and exposure to hot water. Check your toilet tank gasket for signs of wear or damage—if necessary, replace it with a new one. It’s important to ensure a tight seal between the tank and bowl for proper functioning.

Step 7: Examine the Washer in the Fill Valve Assembly

Another common issue is leaking from the fill valve assembly. This could be caused by a worn washer in the fill valve assembly—take a look at the washer to determine if it needs replacing. It’s important to use a genuine Sloan Flushmate replacement part for this repair. That way, you can be sure it’s compatible with your Sloan Flushmate and won’t cause any further damage.

Step 8: Inspect the Toilet’s Flapper Valve

The flapper valve is responsible for controlling how much water enters the toilet bowl when you flush. Check the flapper valve to make sure it’s in good condition, and that no obstructions are preventing it from closing fully. You may need to replace the flapper valve if it’s worn or damaged.

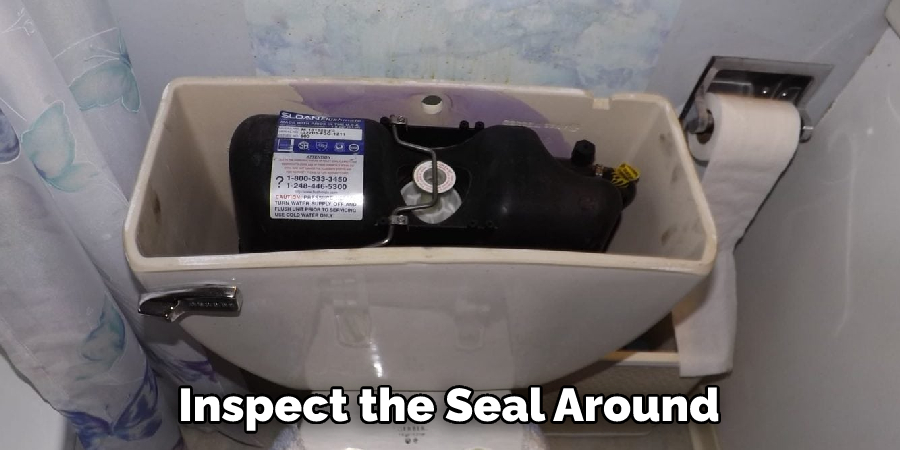

Step 9: Look for Signs of Damage on the Toilet Tank Seal

Inspect the seal around your Sloan Flushmate toilet tank for any signs of wear or damage—if necessary, replace it with a new one. You should also check the bolts that attach the toilet tank to the bowl for any signs of rust or corrosion. It’s important to make sure these bolts remain tight and secure in order for the Sloan Flushmate system to operate properly.

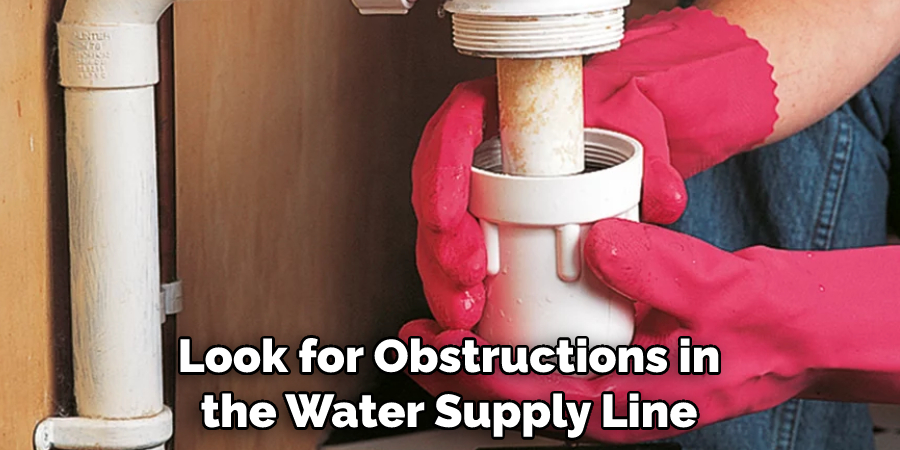

Step 10: Check Your Home’s Water Supply Line

If there is an issue with your home’s water supply, this could be causing a decrease in flush power. Make sure that the line running from your water supply to the Sloan Flushmate is clean and free of obstructions. It’s also important to check the pressure of your water supply line—if it is too low, this could be causing a decrease in flush power.

Step 11: Tighten Connections on the Sloan Flushmate Unit

Loose connections can cause decreased efficiency and loss of pressure. Inspect all connections on the Sloan Flushmate unit, as well as its connecting pipes, and make sure they are secure.

You may need to use a wrench or pliers to tighten them up. You should also use non-toxic, food-grade sealant to reseal any joints that appear to be leaking.

Step 12: Replace Any Worn or Damaged Parts

Make sure to inspect any parts you can easily access for signs of wear or damage—if necessary, replace them with new parts from your local hardware store. It’s always best to use parts and seals that are specifically designed for the Sloan Flushmate. You can also contact the manufacturer for assistance if needed.

Step 13: Turn Off the Water Supply and Disconnect the Sloan Flushmate Tank

If you’re unable to fix a problem with your Sloan Flushmate tank, it may be necessary to disconnect it from the water supply. Before doing this, make sure to turn off the water supply and disconnect the toilet tank from its plumbing lines. You can then take the tank to your local hardware store for further inspection.

Step 14: Replace Your Sloan Flushmate Unit

If all else fails, it may be necessary to replace your entire Sloan Flushmate unit. Make sure to purchase a new one that is compatible with your existing plumbing setup. You may need to enlist the help of a professional plumber to ensure that your new unit is installed correctly. It’s important to use the correct parts and procedures when installing a new Sloan Flushmate toilet to ensure that it functions properly.

Step 15: Reinstall Your New Sloan Flushmate Unit

Once you have purchased a new Sloan Flushmate unit, you will need to reinstall it back into your plumbing lines. Make sure that all connections are secure and the unit is properly installed before using it. It’s important to follow the manufacturer’s instructions and safety guidelines when completing this step.

Following these steps on how to repair sloan flushmate toilet, should help you repair any issues you are having with your Sloan Flushmate toilet. If the problem persists, contact a professional plumber for further assistance. With proper maintenance and care, your Sloan Flushmate toilet should continue to operate smoothly and effectively for years to come.

Frequently Asked Questions

Q: How Often Should I Check My Sloan Flushmate for Repairs?

A: It is recommended that you inspect your Sloan Flushmate regularly for any signs of wear or damage. If necessary, replace any worn parts with new ones from your local hardware store. Additionally, it is important to make sure all connections are tight and secure.

Q: What Should I Do if My Sloan Flushmate is Not Flushing Properly?

A: If your Sloan Flushmate is not flushing properly, you should inspect it for any signs of wear or damage. Additionally, ensure that all connections are secure and look for obstructions in the water supply line. If necessary, you may need to replace the unit with a new one.

Q: What Should I Do if My Sloan Flushmate is Leaking?

A: If your Sloan Flushmate is leaking, it could be caused by a worn washer in the fill valve assembly—inspect the washer and replace it with a new one if necessary. Additionally, make sure all connections are secure and inspect the seal around your toilet tank for any signs of wear or damage. If necessary, replace it with a new one. If the leak persists, contact a professional plumber for further assistance.

Q: How Do I Maintain My Sloan Flushmate?

A: To properly maintain your Sloan Flushmate, you should make sure to inspect it regularly for signs of any wear or damage. Additionally, make sure all connections are secure and look for obstructions in the water supply line. Finally, replace any worn parts with new ones from your local hardware store.

By keeping up with regular maintenance, you can help to ensure that your Sloan Flushmate will continue to operate smoothly and effectively for years to come.

Do You Need Professionals Support?

If you need help with repairing or replacing your Sloan Flushmate, it’s best to contact a professional plumber. They can help to identify the exact problem and recommend the necessary repairs. Professional plumbers are trained in handling these types of toilet issues and can ensure that your Sloan Flushmate is properly installed and functioning correctly.

Conclusion

If your Sloan Flushmate toilet isn’t flushing properly and you’re looking for ways to get it back into working order, then you’ve come to the right place. In this blog post, we’ll go over some of the most common causes of malfunction and how to fix them. You’ll learn what tools are needed for maintenance and repairs, as well as advice on how to avoid future problems.

We’ll discuss both DIY methods and other troubleshooting steps that can be taken by a licensed Sloan service technician when things get serious. By following these simple instructions on how to repair sloan flushmate toilet, you can save yourself time and money in getting your flush mate back up and running!