Are you tired of the constant sound of running water in your toilet? It could be a sign that you need to replace your toilet flapper. A toilet flapper is an essential component of a standard flush system, as it regulates water flow from the tank to the bowl.

How to replace a toilet flapper is a quick and simple repair that can save water, prevent leaks, and improve your toilet’s efficiency. The flapper is a rubber or plastic component inside the toilet tank that controls water flow from the tank to the bowl when you flush. Over time, flappers can wear out, crack, or lose their seal, leading to constant running water or incomplete flushes.

Luckily, with just a few tools and some basic steps, you can quickly replace a faulty flapper and restore your toilet to proper working condition.

What Are the Causes of a Faulty Flapper?

There are several reasons why your flapper may become faulty and require replacement. Some common causes include:

- Normal Wear and Tear: Like any other part, flappers can wear out over time due to repeated use.

- Mineral Build-up: Hard water can cause mineral deposits to build up on the flapper, causing it to lose its flexibility and seal.

- Poor Quality Materials: Low-quality flappers may deteriorate more quickly than higher-quality ones.

- Damage from Cleaning Products: Harsh chemicals in toilet cleaning products can damage the flapper’s rubber or plastic.

What Will You Need?

To properly replace a flapper, you will need the following tools and materials:

- Old Towels or Rags

- Bucket

- Adjustable Wrench or Pliers

- Replacement Flapper (make sure to check the size and type required for your specific toilet)

- Rubber Gloves

Once you have gathered your supplies, you are ready to begin the replacement process.

10 Easy Steps on How to Replace a Toilet Flapper

1. Turn Off the Water Supply

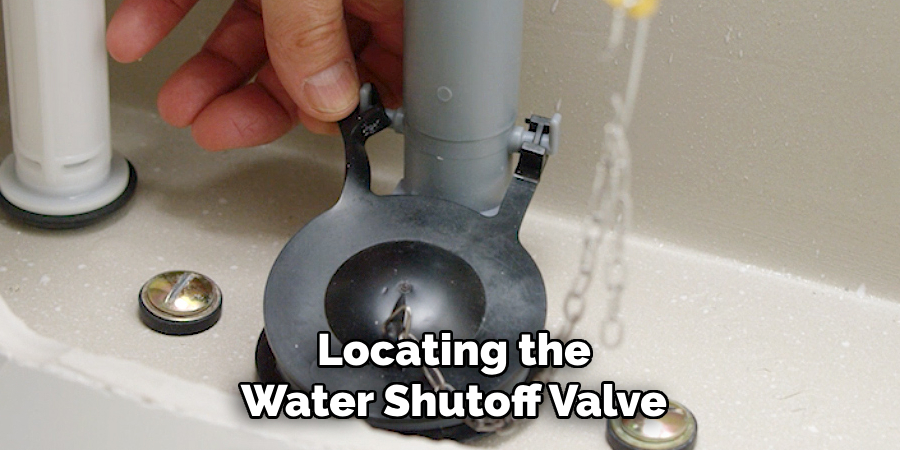

Begin by locating the water shutoff valve behind your toilet. This valve is usually situated at the base of the wall, near where the toilet connects to the water supply line. Turn the valve clockwise until it is completely closed to stop water flow to the toilet.

Once the water supply is off, flush the toilet to drain as much water as possible from the tank. Use old towels or rags to soak up any remaining water in the bottom of the tank, ensuring the area is dry and ready for the flapper replacement process. This step prevents any unnecessary mess or water spillage during the repair.

2. Drain the Tank

Once the tank has been drained, it’s essential to confirm that no water remains that could interfere with the replacement process. After soaking up any residual water with towels or rags, take a moment to inspect the tank for any debris, mineral buildup, or wear that may have accumulated over time.

Cleaning the inside of the tank with a damp cloth or sponge can help you ensure a smooth surface for the new flapper to sit against, reducing the risk of leaks. Be sure to carefully inspect the flush valve seat, as this is where the flapper creates a watertight seal. Any damage or buildup here could compromise the functionality of the new flapper. These additional steps will set the stage for a successful and efficient repair.

3. Disconnect the Old Flapper

To disconnect the old flapper, turn off the toilet’s water supply. Locate the shut-off valve, typically found on the wall or floor behind the bathroom, and turn it clockwise until it is fully closed. Next, flush the toilet to drain as much water as possible from the tank. You may need to use a sponge or towel to remove any remaining water from the bottom of the tank.

Once the tank is empty, locate the flapper at the bottom, which is connected to the flush valve. Inspect the flapper arms, which are usually attached to small hooks on the sides of the overflow tube. Gently unhook the arms from the overflow tube, not damaging any surrounding components. Additionally, examine the chain or strap connecting the flapper to the flush handle lever, and disconnect it by unhooking it from the lever or detaching it from the flapper itself.

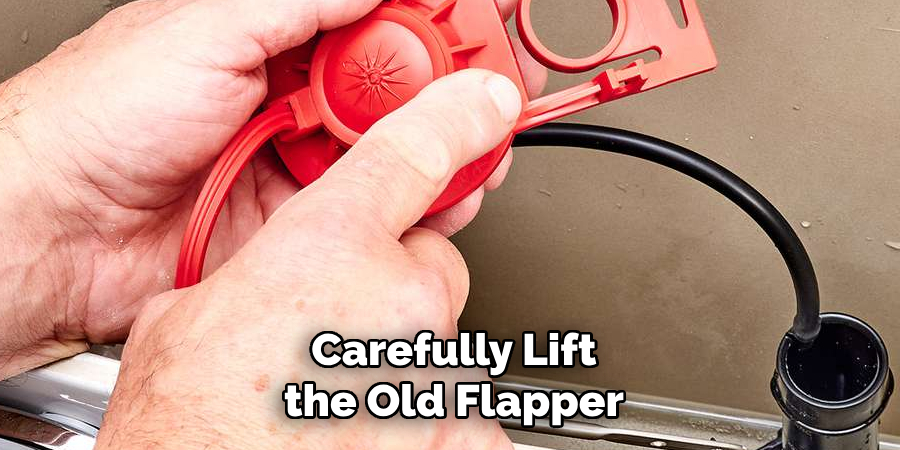

4. Remove the Old Flapper

Carefully lift the old flapper from the tank, ensuring you do not spill any remaining water. Inspect the area around the flush valve seat for any dirt, mineral deposits, or residual gasket material buildup that might interfere with the seal. Use a clean cloth or sponge to wipe down the valve seat and the surrounding area. If necessary, use a non-abrasive brush to gently remove stubborn deposits, being cautious not to scratch or damage the surfaces. Dispose of the old flapper properly, as it may have become brittle or warped over time.

5. Inspect the Flush Valve Seat

With the old flapper removed, carefully inspect the flush valve seat for any signs of damage, wear, or residue buildup. The flush valve seat is where the flapper seals to prevent water from leaking into the toilet bowl. If mineral deposits, grime, or debris are around the seat, clean it thoroughly using a sponge or a non-abrasive cleaning pad to ensure a proper seal for the new flapper.

A mild cleaner or vinegar solution can be applied for stubborn residue to break down the buildup. If the flush valve seat shows signs of cracks or significant wear, it may need to be replaced as well, as this could lead to persistent leaks even with a new flapper in place.

6. Install the New Flapper

Position the new flapper over the flush valve seat at the bottom of the tank. Attach the flapper’s side hooks or clips to the overflow tube, ensuring it is secure. Make sure the flapper sits evenly and covers the flush valve opening completely.

7. Reconnect the Chain

Attach the chain from the flapper to the trip lever, ensuring there is just enough slack for the flapper to open and close properly when the toilet is flushed. Avoid leaving too much slack, as this could prevent the flapper from sealing the flush valve tightly. Test the chain connection by pressing the flush handle to ensure smooth operation. Adjust the chain length if necessary for optimal performance.

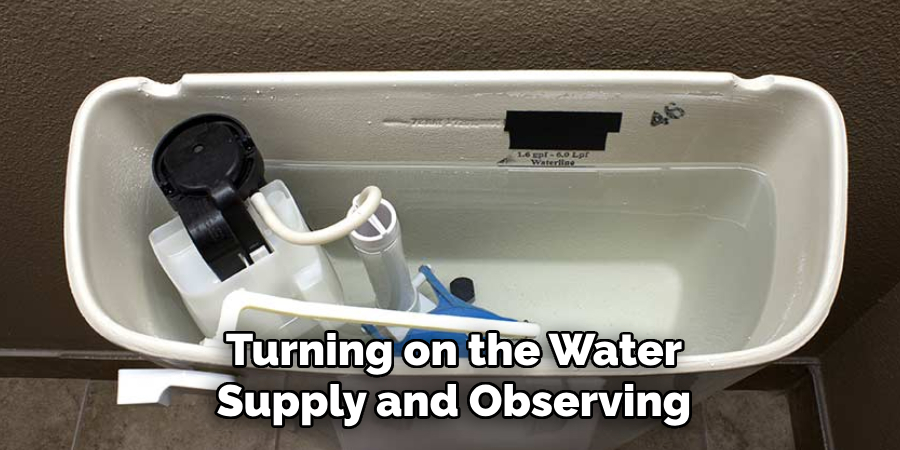

8. Turn the Water Supply Back On

Slowly turn the water supply valve counterclockwise to restore water flow to the tank. Allow the tank to fill, and observe for any leaks around the base of the flapper or other connections. Flush the toilet a few times to ensure all components are working correctly and the repair has been successful. If you notice any issues, inspect the chain, flapper, and water connections for adjustments.

9. Test the Flush

Once the tank has filled, press the flush handle to test the repair. Ensure the water flows smoothly from the tank into the bowl without any delays or irregularities. Check that the flapper closes securely after the flush, preventing water from continuously running. Listen for any unusual sounds and verify that the toilet refills properly to the correct water level. If everything appears to be functioning as intended, your repair is complete. If problems persist, recheck the installation and make necessary adjustments.

10. Adjust If Necessary

After making necessary adjustments, test the toilet again to ensure optimal performance. Pay close attention to the consistency of the flush and the speed at which the water refills. If the flush is too weak or the refill is too slow, double-check the water supply valve to ensure it is fully open and inspect for any potential blockages in the fill valve or the supply line. Additionally, examine the alignment of the flapper and chain to confirm they are not too loose or too tight, as this can impact the effectiveness of the flush. For persistent leaks or difficulties, consider replacing worn components, such as seals or washers, which may have degraded over time.

By following these simple steps and performing regular maintenance, you can keep your toilet running smoothly and prevent costly repairs or replacements.

5 Things You Should Avoid

- Using the Wrong Flapper Size

Ensure that the flapper you purchase is the correct size for your toilet. Using the wrong size can lead to improper sealing, leaks, and water waste.

- Neglecting to Turn off the Water Supply

Before beginning, always shut off the water supply to the toilet. Failing to do so can cause water to spill and create an unnecessary mess during the replacement process.

- Reusing an Old Chain or Handle Mechanism

Avoid reusing worn or corroded components like the chain or handle mechanism when replacing the flapper. These parts can fail over time and compromise the new flapper’s function.

- Improperly Securing the Flapper

Ensure the flapper is securely attached to the flush valve and properly aligned. A flapper that is loosely or incorrectly installed can lead to inefficient flushing and leaks.

- Skipping a Leak Test After Installation

After replacing the flapper, always perform a leak test by turning on the water supply and observing the toilet’s performance. Skipping this step could leave undetected leaks, resulting in higher water bills.

Conclusion

How to replace a toilet flapper is a straightforward task that can significantly improve the efficiency of your toilet and reduce water waste.

By following the steps carefully, such as turning off the water supply, removing the old flapper, installing the new one correctly, and performing a leak test, you can ensure the job is done effectively. Taking the time to address this issue promptly can save money on water bills and prevent potential problems.

Maintaining a properly functioning toilet flapper is a simple yet essential aspect of home plumbing care.