Tiling around a shower valve may seem like a daunting task, but with the right tools and guidance, it can be accomplished effectively and professionally. Properly tiling this area is crucial not only for aesthetic purposes but also to ensure water resistance and prevent potential leaks. This guide will provide you with clear, step-by-step instructions on how to tile around shower valve.

Why Proper Tiling Around a Shower Valve Is Important

Proper tiling around a shower valve is essential for both functional and aesthetic reasons. A well-tiled area ensures that water does not seep behind the tiles, which can lead to moisture buildup, mold growth, and eventual damage to the wall structure. Additionally, securely placed tiles help maintain the integrity of the shower by creating a durable and water-resistant surface. From a visual standpoint, neatly tiled edges around the valve contribute to a polished and professional appearance, complementing the overall design of the shower. Without proper tiling, you may face costly repairs and frequent maintenance in the future.

Tools and Materials You’ll Need

To properly tile around a shower valve and ensure both functionality and aesthetics, you’ll need the following tools and materials:

Tools

- Tile cutter or wet saw

- Notched trowel

- Grout float

- Level

- Measuring tape

- Tile spacers

- Utility knife

- Sponge

- Drill with hole saw attachment (for cutting around the valve)

Materials

- Ceramic, porcelain, or stone tiles (your choice based on design preferences)

- Thin-set mortar or tile adhesive

- Grout (choose a color that complements your tiles)

- Tile edging trim

- Sealant or caulk (for waterproofing)

- Cleaning cloths

Ensuring you have these tools and materials on hand will make the process smoother and help achieve a professional-grade finish.

10 Methods How to Tile around Shower Valve

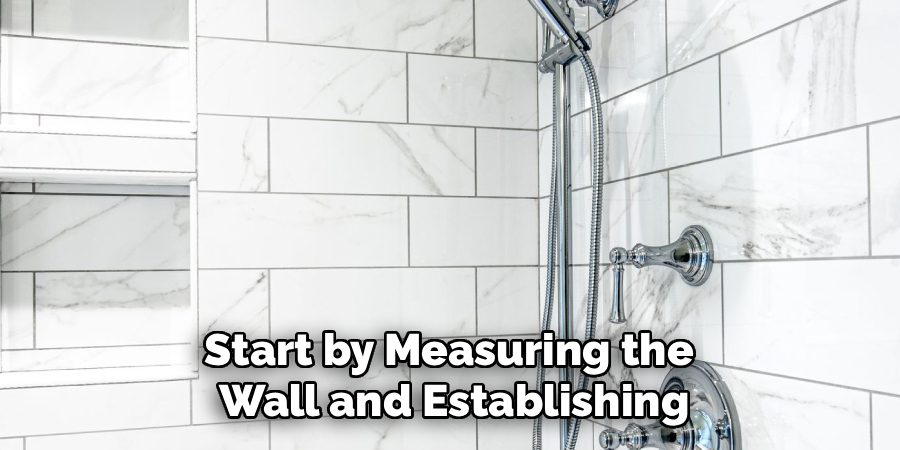

1. Plan the Tile Layout Before You Begin Cutting

Before you cut any tiles or apply adhesive, it’s essential to plan your tile layout around the shower valve. Start by measuring the wall and establishing the center lines both vertically and horizontally. Dry-lay a few rows of tile to see where they land in relation to the valve. Try to position the valve in the center of a tile or grout joint for the cleanest look. Avoid placing small slivers of tile around the valve, as they can look awkward and are harder to cut and secure. A well-planned layout not only improves aesthetics but also simplifies the cutting process.

2. Measure the Shower Valve Opening Accurately

Once your layout is set, take precise measurements of the valve’s location. Use a tape measure to determine the distance from the valve center to the edges of adjacent tiles or walls. Also, measure the diameter of the valve body (not including the escutcheon or trim plate). Add an extra 1/8 to 1/4 inch around the valve for expansion and to ensure the trim plate fits comfortably. Double-check your measurements before marking any tile. Precision here is critical to a snug, clean opening.

3. Use a Hole Saw or Diamond Bit for Circular Cuts

To create a clean, round opening in your tile for the shower valve, use a diamond-coated hole saw or tile drill bit. Choose a hole saw that’s slightly larger than the valve body (typically 1 ¼” to 2 ½”, depending on the valve). Secure the tile to a scrap piece of wood or a sacrificial surface, mark your center point, and drill slowly with constant water to cool the bit and minimize dust. This method produces a professional-looking circular cut and prevents tile cracking.

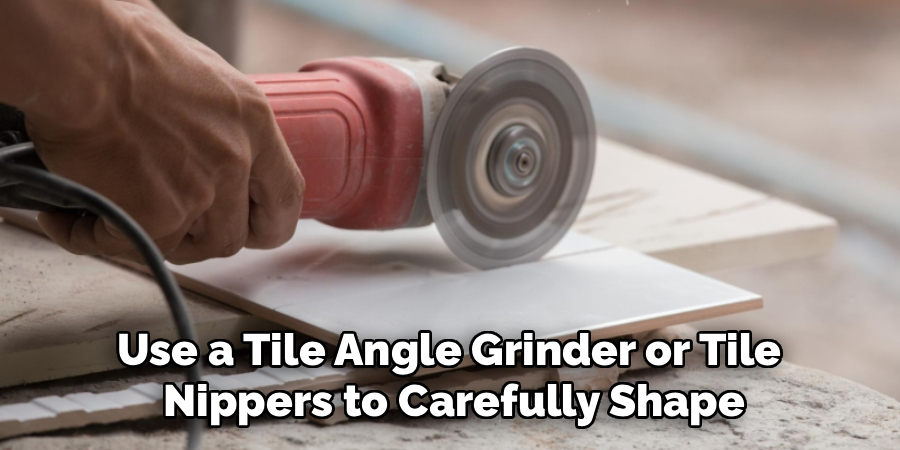

4. Cut Partial Circles with an Angle Grinder or Nippers

If the valve is near a tile edge or falls between multiple tiles, you may need to cut partial circles instead of full holes. Use a tile angle grinder or tile nippers to carefully shape each piece to fit around the valve. Score the outline first with a tile cutter or Dremel, then slowly remove material in small increments. Dry-fit the tile around the valve frequently to ensure a tight fit. This method requires patience but allows you to work with complex layouts or irregular placements.

5. Dry-Fit the Tiles Around the Valve Before Installing

Before setting any tile in mortar or adhesive, dry-fit all the cut tiles around the valve. This allows you to make minor adjustments, smooth rough edges, or correct measurement errors. Fit the tiles in place with spacers to simulate final positioning. The valve should sit comfortably within the cutout, and the trim plate should cover the edges of the tile opening without gaps. A proper dry-fit ensures fewer surprises when you commit to the installation.

6. Use Tile Spacers to Maintain Grout Line Continuity

As you tile around the valve, it’s important to keep grout lines consistent with the rest of the wall. Use tile spacers to maintain proper spacing between tiles, especially when working with smaller cut sections. Uneven grout lines can make even the most precisely cut tile job look unprofessional. Align spacers vertically and horizontally to guide the layout. Once the adhesive sets, remove the spacers and inspect the lines again before grouting.

7. Set Tiles with Thin-Set Mortar for a Strong Bond

Apply thin-set mortar using a notched trowel to set the tiles around the valve. Spread the mortar evenly, then press the tile firmly into place with a slight twisting motion to ensure full contact with the wall. Be cautious not to push excess mortar into the valve opening. Clean away any excess immediately with a damp sponge. Thin-set provides a strong, lasting bond and is ideal for wet environments like showers. Allow the adhesive to cure fully before proceeding to the next step.

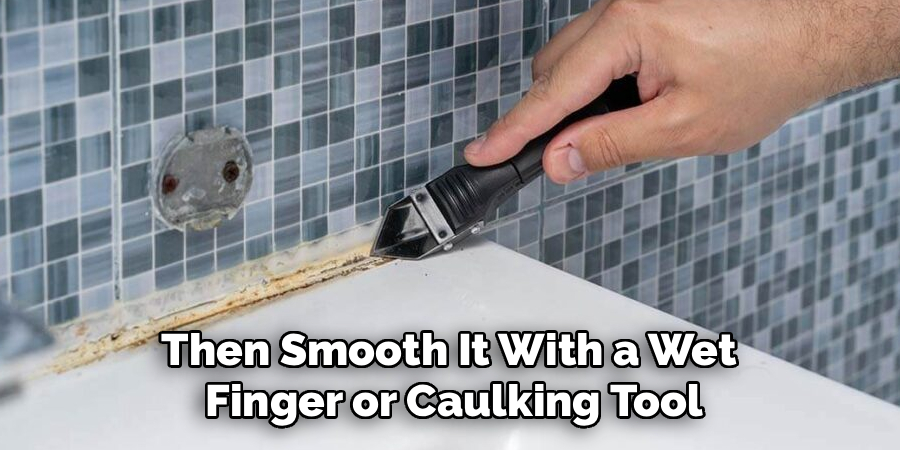

8. Seal the Gap Around the Valve with Silicone Caulk

After the tile is installed and grouted, seal the small gap between the valve body and tile edge with 100% silicone caulk. This waterproof barrier prevents moisture from seeping behind the wall and causing damage. Apply the caulk smoothly and evenly around the valve perimeter, then smooth it with a wet finger or caulking tool. Allow it to dry completely before installing the trim plate or turning on the water. Silicone provides flexibility and durability in a high-moisture environment.

9. Install the Escutcheon Plate and Handle Carefully

Once everything is sealed and dry, finish the job by installing the escutcheon plate (trim plate) and shower handle. The plate should cover the tile cutout completely and sit flush against the wall. Some plates have a foam or rubber gasket to create a watertight seal; if yours doesn’t, apply a small bead of silicone behind the plate before pressing it into place. Secure it with the provided screws and attach the handle per the manufacturer’s instructions. A clean, snug trim finish is the final touch that completes the look.

10. Perform a Final Leak and Fit Check

Before using the shower regularly, perform a final check to ensure everything is functioning correctly. Turn on the water and operate the valve, checking for any leaks behind the trim plate or at the tile seams. Ensure the handle moves freely and the valve turns off properly. If you notice any moisture or wobbling, tighten fittings or reapply silicone as needed. Taking time for this final inspection helps prevent future water damage and ensures your tile job holds up for years to come.

Things to Consider When Installing a Shower

Installing a shower involves careful planning and attention to detail to ensure a successful outcome. Here are a few key factors to keep in mind:

- Waterproofing: Proper waterproofing is essential to prevent water from seeping into walls and floors, which can lead to mold and structural damage. Use waterproof membranes and sealants as needed.

- Drainage: Ensure the shower floor is sloped correctly toward the drain to avoid standing water. A poorly designed slope can cause water pooling and long-term issues.

- Material Selection: Choose durable, water-resistant materials for tiles, grout, and fixtures. Opt for products that are easy to clean and maintain to enhance the shower’s longevity.

- Ventilation: Proper airflow is crucial to prevent excess moisture buildup. Installing a vent or ensuring natural air circulation can help reduce humidity and maintain a healthy bathroom environment.

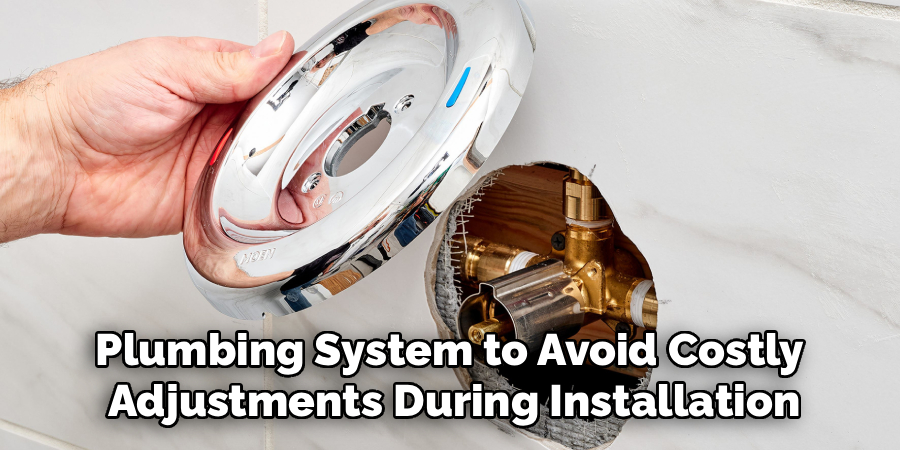

- Plumbing Compatibility: Double-check that your chosen fixtures are compatible with your existing plumbing system to avoid costly adjustments during installation.

By carefully considering these aspects, you can ensure your shower is safe, functional, and aesthetically pleasing.

Conclusion

Tiling around a shower valve is one of those finishing touches that requires attention to both detail and function. While it may involve precise measuring, careful cutting, and meticulous sealing, each step contributes to a professional and waterproof shower finish. From planning your layout to applying silicone and securing trim plates, these ten elaborated methods provide a step-by-step path to success. Thanks for reading our blog post on how to tile around shower valve! We hope you found it helpful and informative.